In the demanding world of complex large-scale part machining, manufacturers often wrestle with challenges such as maintaining high precision, managing material deformation, and ensuring production stability—particularly when working with composite materials and structural molds. After 18 years collaborating across various sectors, from aerospace to automotive and heavy machinery, one of the most frequent pitfalls procurement professionals encounter is selecting equipment that cannot sustain accuracy under heavy duty or fluctuating loads.

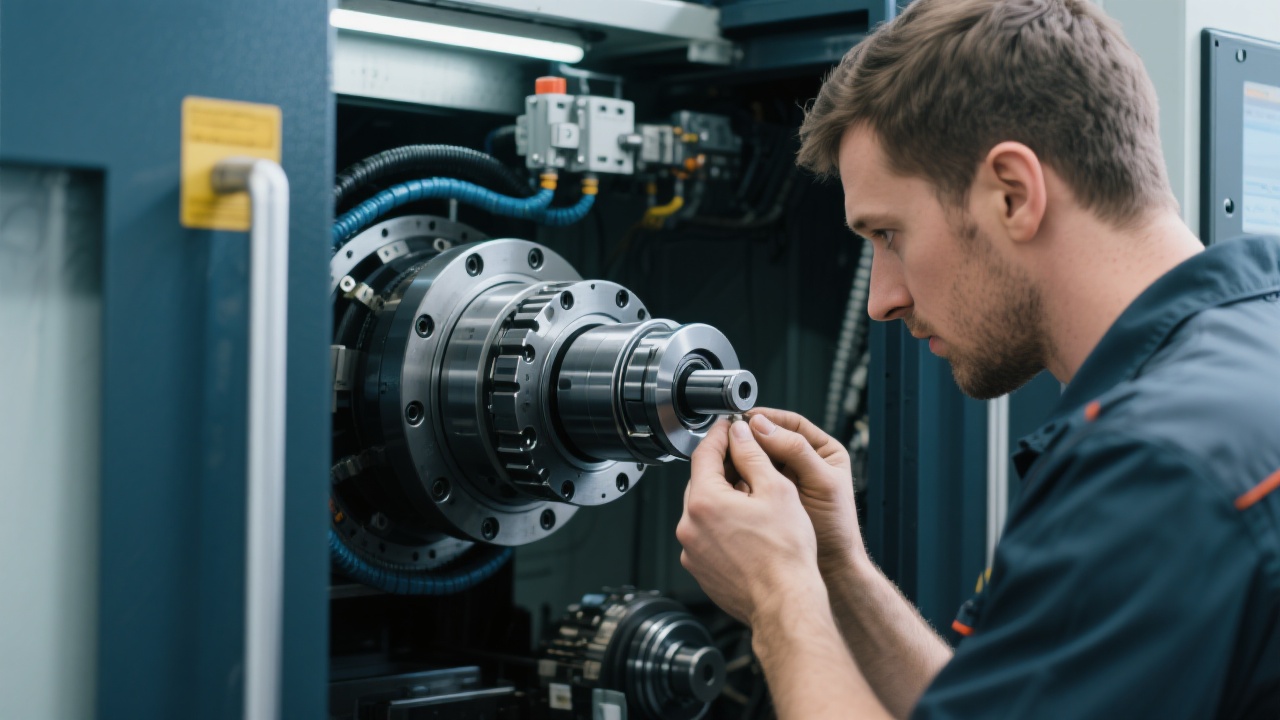

The GV1625 stands out in the crowded CNC milling machine market by offering a meticulously engineered, rigid steel structure that forms the backbone for exceptional machining performance. Unlike conventional gantry or single-column machines, the double column design of the GV1625 provides increased stiffness and resistance against deflection and vibration—a decisive advantage when shaping large composite material parts prone to subtle distortions.

Its robust steel frame minimizes thermal deformation during prolonged cutting operations, ensuring that tolerances as tight as ±0.02 mm are consistently achievable across machining envelopes exceeding 1600 mm in width and 2500 mm in length. This structural integrity directly translates to stable cutting forces, reduced tool chatter, and enhanced surface finish quality—critical factors for aerospace-grade prepreg molds and automotive composite panels.

Manufacturers processing composite structural components understand that flatness and fiber orientation precision are paramount. The GV1625's double column design ensures minimal spindle runout and vibration, preserving the fiber integrity and preventing microscopic delamination or surface defects. Additionally, its advanced CNC control system supports complex tool paths and adaptive feed rates necessary for composite layup molds and intricate part geometries.

Production efficiency is equally enhanced. The machine’s structural rigidity allows for higher cutting speeds and heavier chip loads without sacrificing finish quality. This means throughput is increased, downtime for tool maintenance is reduced, and overall cost per part decreases. Meanwhile, the GV1625’s modular design simplifies maintenance and upgrades, safeguarding long-term investment.

Comparing alternatives, while gantry-style machines may offer larger work areas, they often suffer from deflection under heavy cuts. Conversely, single-column machines may lack the structural span to accommodate large composite panels efficiently. The GV1625 strikes a balanced solution—superior rigidity tailored for complex large parts while optimizing floor space and operational flexibility.

One leading aerospace supplier faced consistent challenges with their prior milling solutions—excessive vibration distorted their prepreg molds, and inconsistent part flatness resulted in a 12% rejection rate. After integrating the GV1625 into their production line, they recorded a 35% reduction in machining cycle times, cut component flatness deviations from ±0.05 mm to ±0.015 mm, and saw scrap rates plummet to below 3% within three months.

Feedback from the production manager highlighted the machine’s reliability under continuous 24/7 operation and the ease of programming complex geometries with the new CNC system. These improvements translated to annual cost savings estimated at over $120,000 in scrap reduction and increased throughput.

| Feature | GV1625 Double Column | Single Column CNC | Gantry Milling Machine |

|---|---|---|---|

| Structural Rigidity | High (Steel Frame with Dual Columns) | Medium | Low to Medium (Larger Span) |

| Max Machining Envelope (mm) | 1600 x 2500 x 800 | 1200 x 1000 x 600 | 2000 x 3000 x 1000 |

| Repeatability (mm) | ±0.01 | ±0.015 | ±0.03 |

| Suitability for Composite Machining | Excellent | Moderate | Less Optimal |

| Maintenance Ease | Modular & Accessible | Standard | Complex |

This comparative analysis underscores the GV1625’s alignment with industry demands for accuracy, structural integrity, and operational efficiency—critical factors when processing high-value composite structural components.

The GV1625 double column CNC milling machine is engineered precisely to resolve the persistent challenges of machining large, complex composite parts. Its rigid steel structure ensures unwavering dimensional accuracy and surface quality, while its advanced CNC capabilities allow for flexible, efficient processing. With proven success stories from demanding aerospace and automotive applications, the machine delivers a tangible return on investment through reduced scrap, enhanced throughput, and minimized operator intervention.

For companies seeking to elevate their composite manufacturing precision and production stability, the GV1625 is a strategic investment aligned with long-term productivity and quality goals.