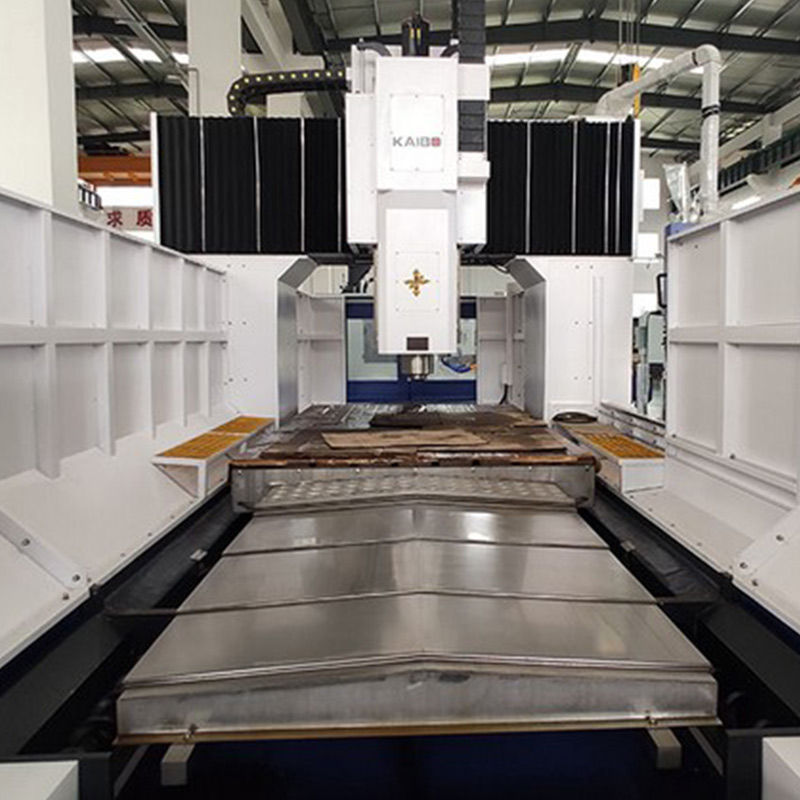

As the demand for precision and stability in iron mold processing continues to rise, manufacturers are increasingly turning to advanced CNC milling machines that can meet these stringent requirements. Among the latest innovations, the DC1113 CNC milling machine stands out due to its unique mobile bridge structure, fixed crossbeam, and fixed worktable design. This article explores how this configuration enhances mechanical strength, stability, and overall performance, making it a reliable choice for long-term production operations.

The iron mold processing industry is highly sensitive to equipment stability and machining accuracy. Any deviation in the manufacturing process can lead to defects, rework, or even product failure. Traditional CNC milling machines often struggle with maintaining consistent precision under heavy loads or over extended periods. As a result, there is a growing need for machinery that offers superior rigidity and reliability.

The DC1113 CNC milling machine incorporates a mobile bridge structure combined with a fixed crossbeam and fixed worktable. This design significantly enhances the machine’s structural integrity and reduces vibration during operation. The mobile bridge allows for smooth and precise movement along the X-axis, while the fixed components ensure minimal deformation under load. Compared to conventional designs, this configuration provides greater mechanical strength and thermal stability, which are crucial for high-precision iron mold processing.

To better understand the advantages of the DC1113, let's compare it with traditional CNC milling machines:

| Feature | DC1113 | Conventional Machines |

|---|---|---|

| Structural Rigidity | High | Moderate |

| Vibration Control | Excellent | Average |

| Precision Retention | Outstanding | Limited |

| Service Life | Longer | Shorter |

The enhanced stability of the DC1113 directly translates into improved machining accuracy, higher product quality, and reduced tool wear. According to internal data, machines with similar configurations have shown a 30% reduction in surface roughness and a 25% increase in tool life. These improvements not only lower production costs but also contribute to a more efficient and sustainable manufacturing process.

Many customers who have adopted the DC1113 report significant improvements in their production workflows. One user from Germany shared, "Since we upgraded to the DC1113, our defect rate has dropped by nearly 40%, and our machine maintenance intervals have increased substantially." Such testimonials highlight the machine’s role in ensuring long-term operational efficiency and cost-effectiveness.

The DC1113 CNC milling machine represents a major advancement in iron mold processing technology. Its mobile bridge structure, combined with fixed crossbeam and worktable, ensures exceptional stability, precision, and durability. For businesses looking to enhance productivity and maintain a competitive edge, the DC1113 is an ideal investment.

If you are interested in learning more about the DC1113 or would like to schedule a consultation, please visit our website at CTA-URL. Our team is ready to support your business growth with cutting-edge solutions tailored to your needs.