Graphite machining is a critical process in industries such as aerospace, automotive, and semiconductor manufacturing. However, it comes with unique challenges that can significantly impact production efficiency, equipment lifespan, and product quality. Understanding these challenges and finding effective solutions is essential for manufacturers aiming to stay competitive in the global market.

Graphite is a brittle material that generates fine dust and metal shavings during machining. These particles can cause severe damage to machine tools, reduce precision, and create hazardous working conditions. According to industry data, up to 40% of machine downtime in graphite processing environments is attributed to dust accumulation and corrosion issues.

Moreover, traditional dry machining methods often fail to contain the fine graphite dust, leading to increased maintenance costs and safety risks. The presence of dust also affects the accuracy of high-precision parts, which is crucial in advanced manufacturing applications.

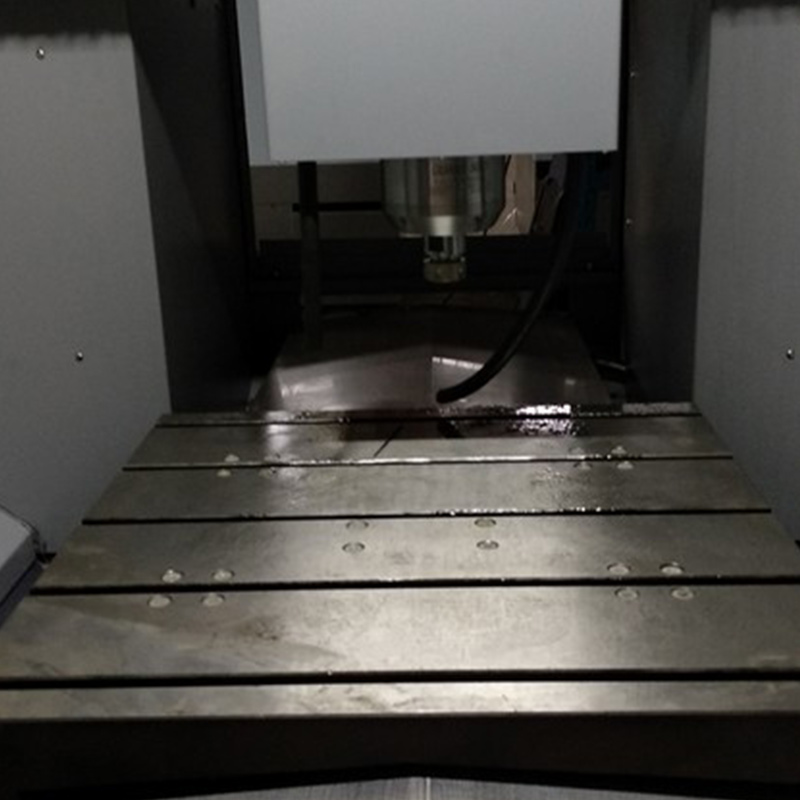

The DC6060G wet-flush graphite machining center is designed to overcome these common challenges by combining proven technology from the DC6060A CNC milling machine with innovative dust control features. This solution ensures a cleaner, safer, and more efficient machining environment.

The DC6060G incorporates a full-sealed enclosure and an advanced wet-flush system to effectively manage graphite dust and metal chips. Compared to conventional dry machining systems, this design reduces dust emissions by over 90%, significantly extending the service life of the machine and improving machining accuracy.

| Feature | DC6060G | Traditional Dry System |

|---|---|---|

| Dust Control Efficiency | 92% | Less than 60% |

| Maintenance Interval | Every 1,500 hours | Every 500 hours |

| Machine Lifespan | Up to 10 years | 5–7 years |

A leading electronics manufacturer in Southeast Asia implemented the DC6060G in their production line to address recurring issues with dust contamination and machine wear. After six months of operation, they reported a 75% reduction in unplanned downtime and a 20% increase in overall productivity. The company also noted improved part consistency and reduced rework rates.

The DC6060G offers a reliable and cost-effective solution for graphite machining. Its advanced dust management system ensures a clean working environment, while its robust design guarantees long-term stability and performance. Whether you are producing high-precision components or large-volume parts, the DC6060G can meet your needs with exceptional efficiency and reliability.

Don’t let dust and debris slow down your operations. Discover how the DC6060G can transform your graphite machining process today. Contact us now to learn more about the DC6060G and schedule a consultation.

If you have any questions or would like to request a detailed specification sheet, feel free to leave a comment below. We’re here to help you make the best decision for your business.