The graphite processing industry has long struggled with challenges such as dust pollution and equipment corrosion, which not only affect product quality but also pose health risks to workers and reduce machine lifespan. As global demand for high-precision graphite components continues to rise, manufacturers are increasingly seeking advanced solutions that ensure efficiency, safety, and sustainability.

The DC6060G wet graphite machining center has emerged as a top choice among international buyers due to its innovative design and superior performance. With a growing number of clients reporting significant improvements in productivity and operational safety, the DC6060G is rapidly becoming a standard in the global graphite processing market.

Building on the proven reliability of the DC6060A, the DC6060G features enhanced structural integrity and precision control. This evolution ensures that the machine maintains high accuracy even under demanding conditions, making it ideal for complex graphite machining tasks.

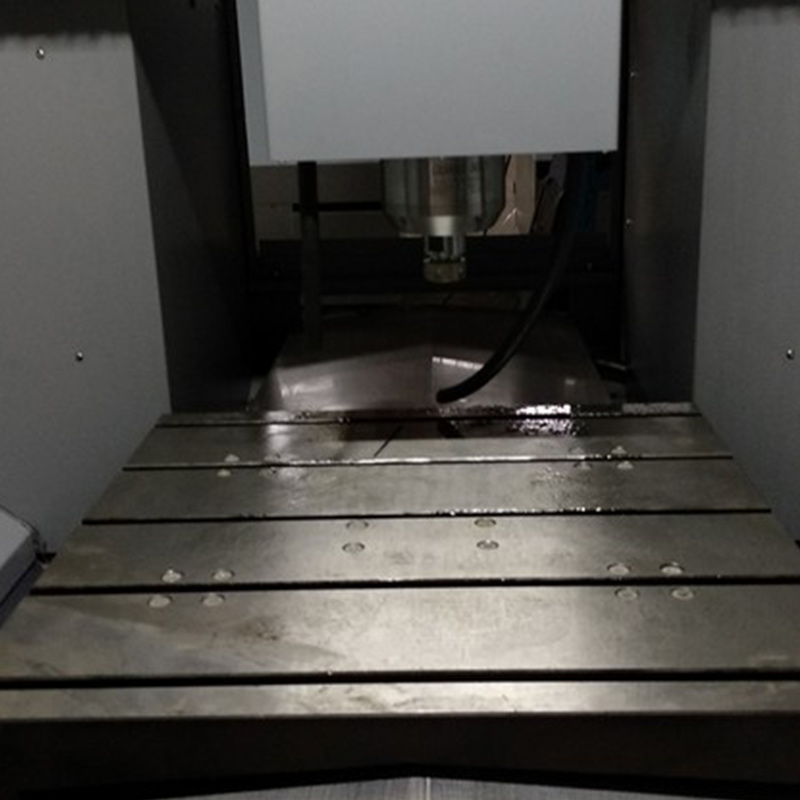

A key innovation of the DC6060G is its full sealed enclosure, which effectively prevents dust and debris from escaping during the machining process. This design not only protects the internal components of the machine from wear and corrosion but also creates a safer and cleaner working environment for operators.

The integrated wet flushing system is another standout feature of the DC6060G. By continuously rinsing the workpiece and tooling area with a controlled flow of coolant, this system significantly reduces residual dust and improves surface finish quality. Users have reported up to a 40% increase in cleaning efficiency compared to traditional dry machining methods.

| Feature | DC6060G | Standard Machine |

|---|---|---|

| Dust Control | Excellent (Sealed Enclosure) | Moderate |

| Coolant System | Integrated Wet Flushing | Basic Spraying |

| Precision | ±0.02mm | ±0.05mm |

One of our clients in Germany, a leading manufacturer of graphite electrodes for the steel industry, reported a 30% reduction in maintenance costs and a 25% improvement in production speed after switching to the DC6060G. Another user in South Korea noted a marked improvement in workplace air quality and operator satisfaction.

The DC6060G is more than just a machine—it's a comprehensive solution designed to meet the evolving needs of the global graphite processing industry. With its advanced sealing technology, efficient cooling system, and precise control, it offers unmatched value for businesses looking to enhance productivity and comply with international safety standards.

Ready to experience the difference? Learn more about the DC6060G today and take your graphite processing operations to the next level.