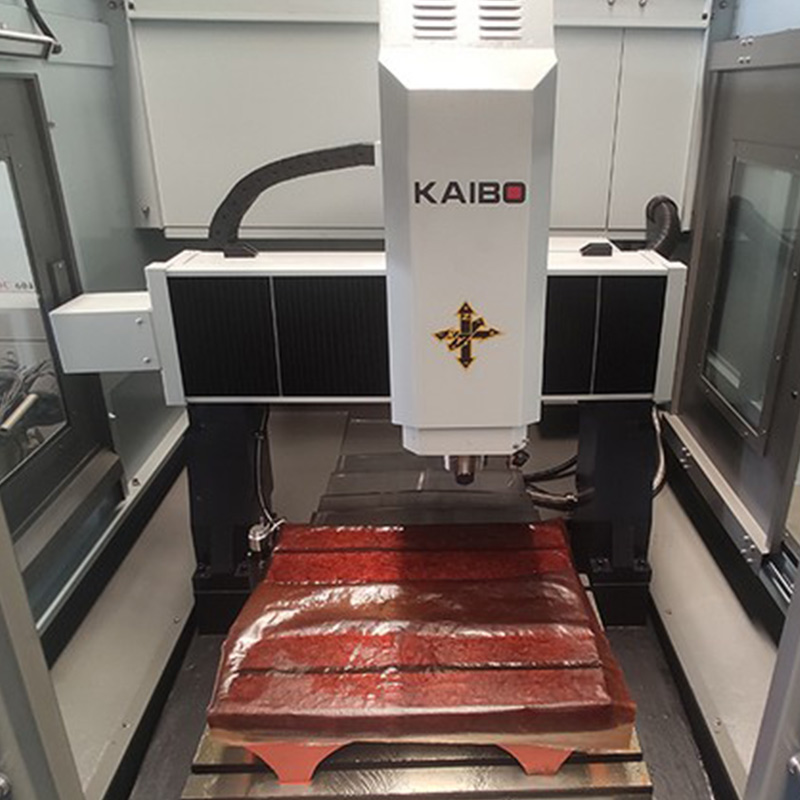

In the competitive world of precision product engraving and mold-making, selecting a high-performance machining center is crucial. The BT40 spindle wheel-type CNC milling machine DC1090A stands out as a robust, mid-sized dual-column milling machine engineered specifically for intricate product engraving and mold processing. This customer success case highlights how the DC1090A has helped manufacturers optimize their production process, improve accuracy, and achieve growth comparable to that offered by traditional vertical machining centers.

The DC1090A is powered by a high-torque BT40 spindle capable of maintaining spindle speeds up to 8000 RPM with remarkable stability and reliability. Its dual-column frame enhances rigidity, reduces vibrations during operation, and ensures superior machining precision—with repeatability accuracy reaching as close as ±0.005 mm. Equipped with advanced CNC control systems and precision linear guideways, the machine facilitates complex engraving tasks with ease.

One of our key clients, a precision components manufacturer specializing in consumer electronics cases, integrated the DC1090A into their production line to address challenges related to detailed engraving and mold-making. Prior to using the DC1090A, their workflow was hampered by frequent tool vibrations and inconsistent engraving depths, impacting product finish and delivery times.

Upon deployment, the customer noted:

These quantifiable improvements empowered the client to reduce rework rates, strengthen on-time delivery, and expand their high-value orders with global OEM customers.

| Feature | DC1090A CNC Milling Machine | Traditional Vertical Machining Center |

|---|---|---|

| Spindle Stability | High stability with BT40 spindle - 8000 RPM max | Variable; often lower RPM and higher vibration |

| Frame Rigidity | Dual-column cast iron frame reduces vibration by 35% | Single-column frames less rigid under high load |

| Precision | ±0.005 mm repeatability | ±0.007 mm to ±0.01 mm |

| Operational Costs | Lower power consumption and maintenance | Higher energy and upkeep costs |

| Suitable Applications | Product engraving, detailed mold making | General machining, heavy-duty milling |

Maximizing the DC1090A’s performance requires adherence to best practices in operation and maintenance:

Have you integrated the DC1090A into your machining workflow? Share your experience or questions below. We invite you to join our community of manufacturing professionals and discover how this advanced CNC milling machine can drive measurable results in your production line.