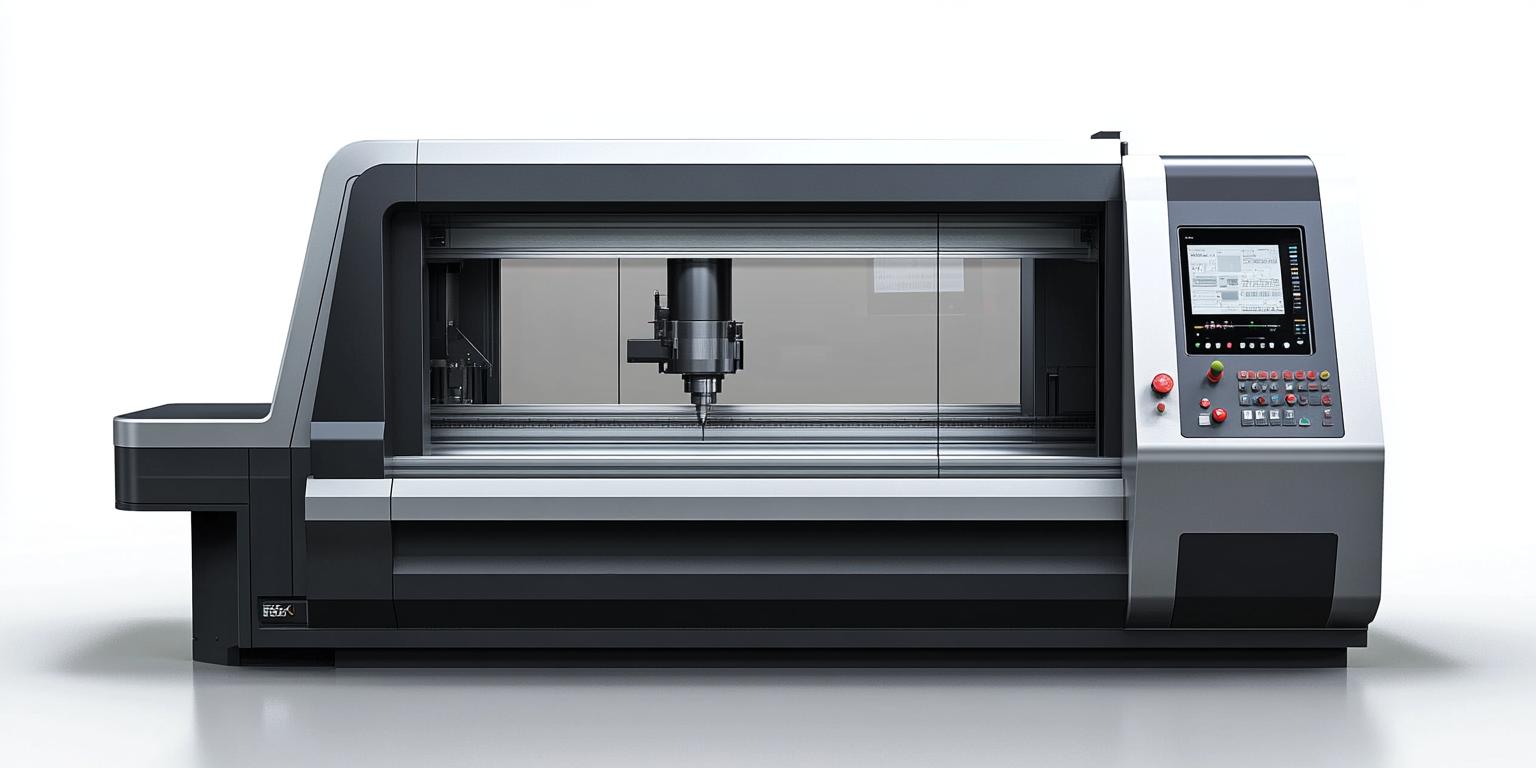

As global demand for high-precision graphite components continues to rise, manufacturers are increasingly turning to advanced machining solutions that can meet the challenges of dust control, corrosion prevention, and long-term reliability. The DC6060G Wet Flush Graphite Machining Center has emerged as a game-changer in this field, offering a combination of innovation, durability, and performance that sets it apart from conventional systems.

The DC6060G is built upon the proven foundation of the DC6060A CNC milling machine, incorporating significant technological advancements that enhance both precision and operational efficiency. With an accuracy of ±0.02 mm, the DC6060G ensures consistent quality across large-scale production runs, reducing waste and rework time significantly.

One of the key improvements is the user-friendly interface and enhanced automation features, which streamline setup and operation. This makes the machine ideal for both experienced machinists and new operators, ensuring a smooth learning curve and faster time-to-market for customers.

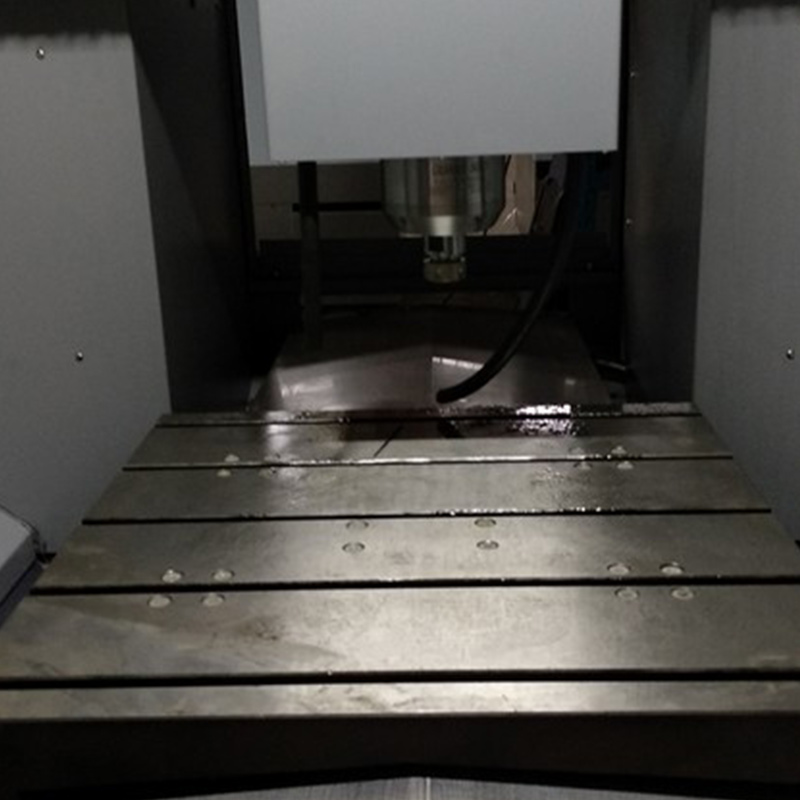

A major challenge in graphite machining is the accumulation of fine dust and metal shavings, which can damage internal components and reduce machine lifespan. The DC6060G addresses this issue with its full-sealed enclosure and integrated wet flush system.

Compared to traditional dry vacuum systems, the wet flush technology effectively captures and removes debris using a controlled water flow. This not only prevents contamination but also extends the life of critical electronic and mechanical parts by up to 40%, according to internal testing data.

| Feature | Traditional Dry Vacuum | DC6060G Wet Flush |

|---|---|---|

| Dust Removal Efficiency | 75% | 98% |

| Component Lifespan Extension | 15% | 40% |

| Machine Accuracy Retention | 6 months | Over 12 months |

A leading manufacturer in the semiconductor industry recently adopted the DC6060G to improve their graphite electrode production process. Prior to this, they faced frequent downtime due to dust buildup and component wear, resulting in inconsistent output and increased maintenance costs.

After implementing the DC6060G, the company reported a 35% increase in production efficiency and a 50% reduction in maintenance requirements. The machine’s ability to maintain a clean working environment also improved workplace safety and compliance with ISO standards.

The DC6060G is more than just a machining center—it's a comprehensive solution designed for modern manufacturing needs. Its advanced design, superior dust control, and ease of use make it an ideal choice for industries such as aerospace, automotive, and electronics.

With a proven track record of performance and reliability, the DC6060G helps businesses reduce costs, improve product quality, and stay competitive in a rapidly evolving market.

Don’t miss the opportunity to upgrade your production line with the DC6060G. Whether you're looking to increase efficiency, reduce maintenance, or improve product quality, our team is here to help you find the right solution.

Take the next step today—contact us now at CTA-URL to learn more about the DC6060G and how it can benefit your business.