In the highly competitive global manufacturing industry, the efficiency and quality of production are crucial for businesses. Many machining companies often face production bottlenecks due to sub - standard equipment. For example, a small - to - medium - sized machining enterprise in Europe was struggling with low - precision and unstable equipment, which led to a high rejection rate of up to 15% in their product carving and mold processing operations. This not only increased production costs but also damaged the company's reputation in the market.

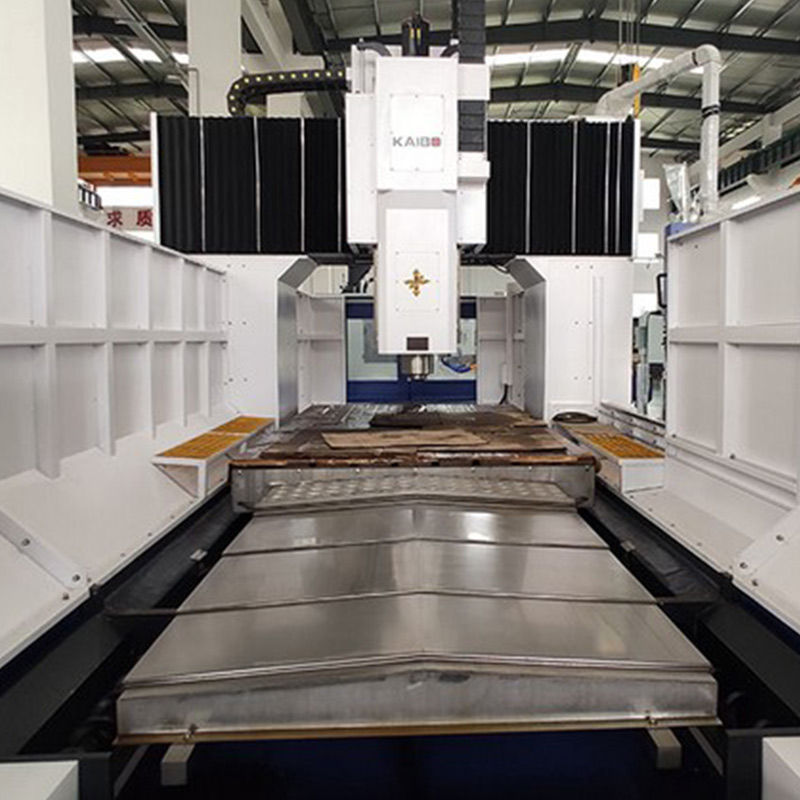

The BT40 Spindle Hub CNC Milling Machine DC1090A is a medium - sized double - column CNC milling machine. Its double - column structure provides excellent stability. Tests have shown that during continuous 24 - hour operation, the vibration amplitude of the machine is controlled within 0.02mm. This high - level stability ensures that the machine can maintain consistent performance during long - term production, reducing the probability of errors caused by machine vibration.

Precision is a key factor in product carving and mold processing. The DC1090A can achieve a positioning accuracy of ±0.005mm and a repeated positioning accuracy of ±0.003mm. These precise data ensure that the machine can accurately process complex shapes and fine details, meeting the high - precision requirements of various industries.

The spindle of the DC1090A is one of its highlights. With a maximum speed of 8000 RPM and a power of 11kW, it can easily handle various materials, from soft plastics to hard metals. Its performance is comparable to that of traditional vertical machining centers, which means that users can get high - end spindle performance at a more cost - effective price.

The DC1090A significantly improves processing efficiency in multiple ways. Firstly, its high - speed spindle and stable structure allow for faster cutting speeds. On average, it can increase the processing speed by 30% compared to similar machines in the market. Secondly, the high precision reduces the need for re - work, saving time and labor costs. In terms of product quality, the high precision and stability ensure that the pass rate of processed products can reach over 98%, which is a significant improvement for enterprises.

A mold manufacturing company in Asia purchased the DC1090A and used it for the production of automotive molds. After using the machine, their production cycle was shortened by 25%, and the rejection rate dropped from 12% to less than 2%. This not only improved their production efficiency but also increased their market competitiveness.

If you are looking for a high - performance, stable, and precise CNC milling machine for your product carving and mold processing needs, the BT40 Spindle Hub CNC Milling Machine DC1090A is the ideal choice. Don't miss this opportunity to enhance your production efficiency and product quality. Contact us now to get more information and start your journey towards better manufacturing!