In the global machining industry, many manufacturers face common challenges. For instance, a medium - sized machining factory in Europe used to struggle with low - quality equipment. Their old milling machines had poor stability, which led to a high scrap rate of up to 15% in the production process. The low precision of these machines also made it difficult to meet the high - standard requirements of customers. As a result, the factory's production efficiency was extremely low, and they often missed delivery deadlines, causing a significant loss of customers.

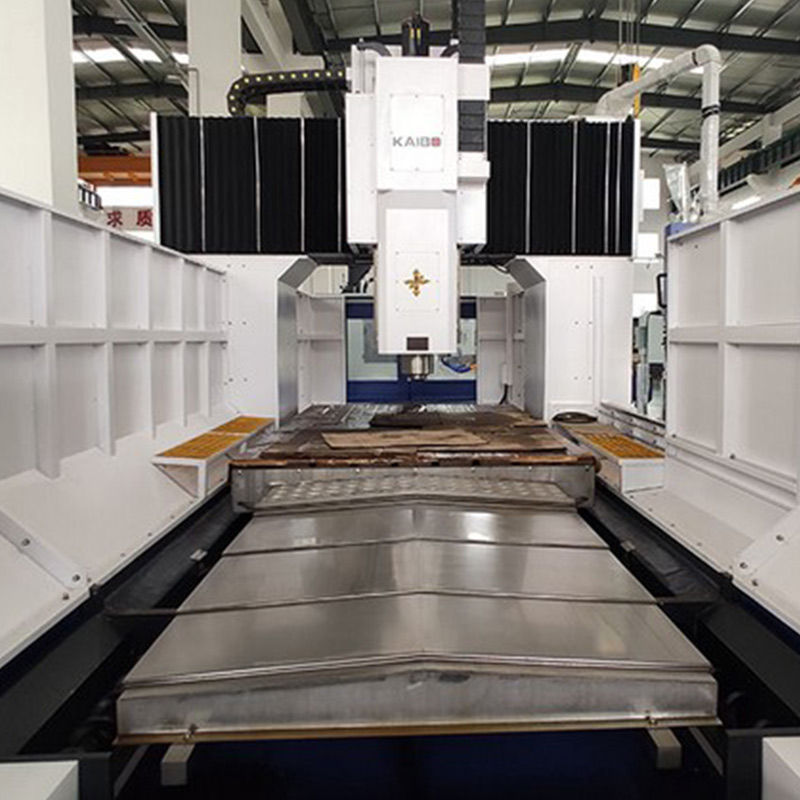

The DC1090A is designed with a double - column structure, which greatly enhances its stability. According to user feedback, after using this machine, the vibration during the machining process is reduced by 70%. This stability allows the machine to operate continuously for up to 20 hours a day without significant wear and tear, ensuring long - term and stable production.

Precision is crucial in the machining industry. The DC1090A can achieve a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm. This high precision ensures that the products meet the strictest quality requirements. Many users have reported that the scrap rate has dropped from 15% to less than 3% after switching to this machine.

The BT40 spindle of the DC1090A has a maximum speed of 8000 RPM, and its power can reach up to 15kW. This spindle capacity is comparable to that of traditional vertical machining centers. It can handle a variety of materials, from soft plastics to hard metals, providing great flexibility in production.

Thanks to its high - speed spindle and stable operation, the DC1090A can increase the production efficiency by 40%. For example, a factory that used to produce 100 parts per day can now produce 140 parts with the same working hours.

The high precision of the machine ensures that the products have a better surface finish and dimensional accuracy. This has helped many companies improve their product quality and gain a better reputation in the market.

The reduction in the scrap rate and the increase in production efficiency have led to significant cost savings. On average, companies can save up to 25% in production costs after using the DC1090A.

A manufacturing company in the United States was facing intense competition in the market. After purchasing the DC1090A, they were able to improve their product quality and reduce production costs. As a result, they won several large - scale orders from European customers, and their market share increased by 15% within a year.

Don't miss out on the opportunity to enhance your production efficiency, improve product quality, and save costs. Contact us today to learn more about the BT40 Spindle Hub CNC Milling Machine DC1090A and take your business to the next level. You can reach us at [Contact Email] or [Contact Phone].