The graphite machining industry has long been plagued by the significant challenges of dust and metal chip pollution. These pollutants not only pose risks to the health of workers but also cause severe damage to machining equipment. Statistics show that in traditional graphite machining centers, up to 70% of equipment failures are related to dust and metal chip contamination. This pollution problem leads to frequent equipment maintenance, increased production costs, and reduced production efficiency, becoming a major obstacle to the development of the graphite machining industry.

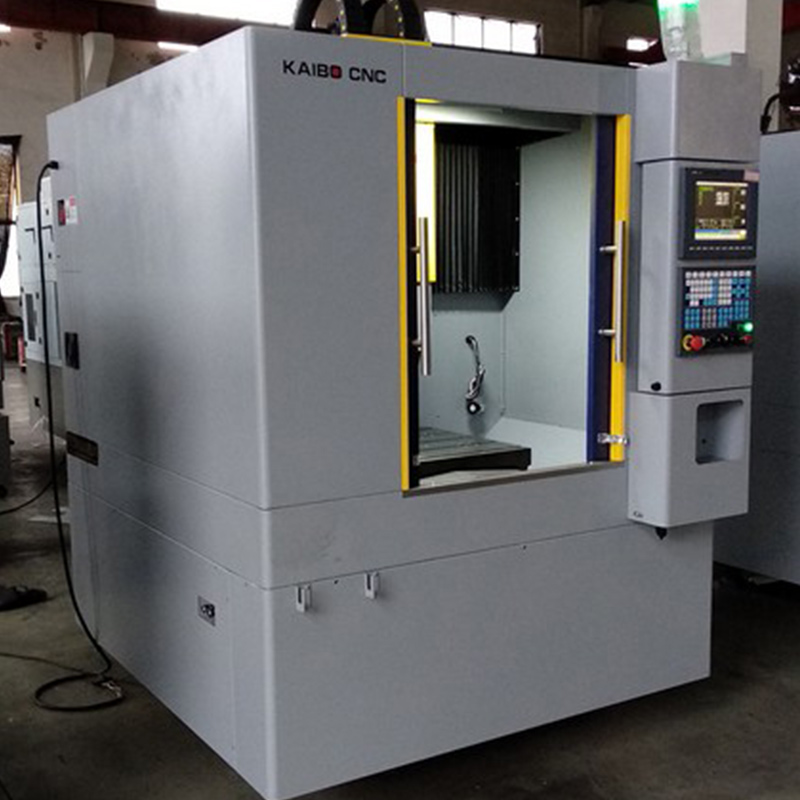

In response to these industry challenges, the Dry Vacuum Graphite Machining Center DC6060G emerges as an efficient solution. This machine is designed based on the CNC milling machine DC6060A, inheriting its high - precision machining capabilities while innovating in terms of pollution control.

One of the key features of the DC6060G is its fully sealed enclosure design. Unlike ordinary machining centers, which are often exposed to the environment during operation, the DC6060G's fully sealed structure effectively isolates the machining area from the external environment. This prevents dust and metal chips from escaping into the workshop, protecting the machine itself from contamination. Tests have shown that this design can reduce the dust diffusion rate in the workshop by up to 90%, significantly improving the working environment.

In addition to the fully sealed enclosure, the DC6060G is equipped with a powerful dust collection system. This system can quickly and effectively collect and remove dust generated during the machining process. It has a dust collection efficiency of up to 95%, ensuring that the machining area remains clean and reducing the impact of dust on the machining accuracy. Compared with ordinary machining centers, which may have a dust collection efficiency of only about 60%, the DC6060G has a significant advantage.

Let's take a look at some real - world examples to see how the DC6060G solves pollution problems. A graphite machining company in Germany used to face high equipment maintenance costs due to dust and metal chip pollution. After replacing their old machining centers with the DC6060G, they found that the equipment failure rate decreased by 60%, and the production efficiency increased by 30%. Another customer in the United States reported that the working environment in their workshop has been greatly improved, and the health risks to workers have been significantly reduced.

We invite you to share your experiences and questions about graphite machining pollution in the comments section below. Have you faced similar problems in your production process? How do you think the Dry Vacuum Graphite Machining Center DC6060G can help you solve these problems? Your insights and feedback are very valuable to us.

Don't let dust and metal chip pollution hold back your production. The Dry Vacuum Graphite Machining Center DC6060G is your ideal choice. Contact us today to learn more about this amazing product and take the first step towards a more efficient and clean graphite machining future!