In the graphite machining industry, dust and metal shavings have long been a headache for manufacturers. These contaminants can cause corrosion and pollution to machine parts and electronic components, leading to frequent equipment failures, increased maintenance costs, and reduced production efficiency. According to industry statistics, nearly 60% of graphite machining equipment failures are related to dust and metal shavings pollution.

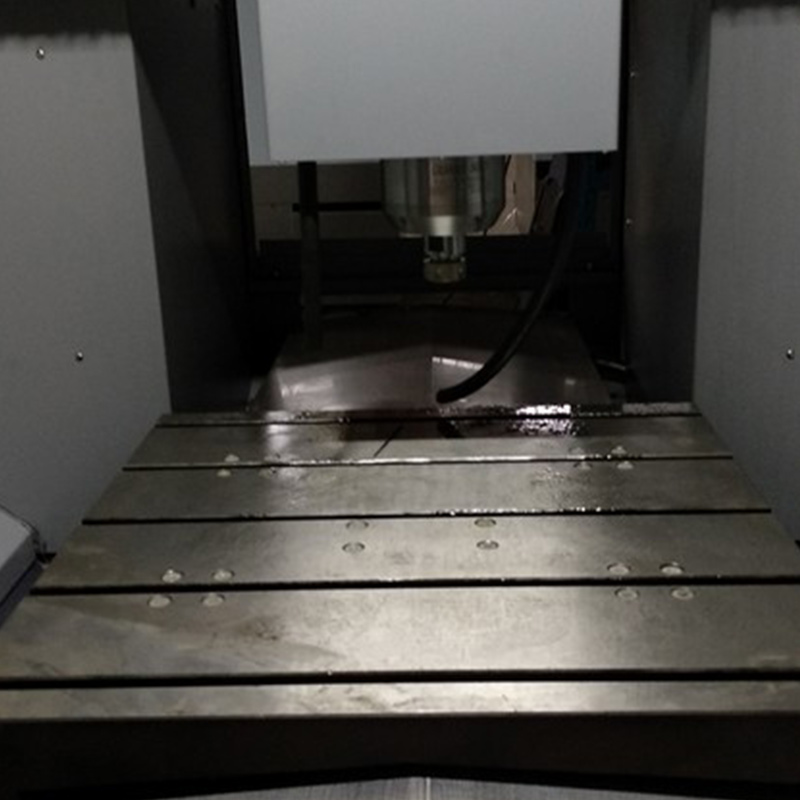

Introducing the DC6060G Dry Vacuum Graphite Machining Center, a revolutionary solution designed to tackle these issues head - on. This machine is an upgraded version based on the DC6060A CNC milling machine, boasting a series of advanced features.

The standout feature of the DC6060G is its fully enclosed hood design. Unlike ordinary machining centers, this design effectively prevents graphite dust and metal shavings from entering the internal components of the machine. As a result, it significantly reduces the risk of corrosion and pollution to the machine parts and electronic components. This not only extends the service life of the equipment but also ensures stable long - term operation.

In addition to the enclosed hood, the DC6060G is equipped with a high - performance dust collection device. This device can efficiently collect and remove graphite dust during the machining process, maintaining a clean working environment. In contrast, regular machining centers often struggle to control dust, which can spread throughout the workshop and pose health risks to workers.

Many customers have already benefited from the DC6060G. For example, a graphite manufacturing company in Germany used to face frequent machine breakdowns due to dust pollution. After switching to the DC6060G, they saw a 40% reduction in equipment maintenance costs and a 30% increase in production efficiency. Another customer in Japan reported that the clean working environment created by the DC6060G improved the health and morale of their workers.

These real - world cases demonstrate the effectiveness of the DC6060G in solving the dust and metal shavings pollution problems in graphite machining.

Are you still struggling with graphite machining dust issues? Do you want to improve your production efficiency and reduce costs? Share your thoughts and experiences in the comments below. And if you're ready to take your graphite machining to the next level, don't hesitate to contact us for more information about the DC6060G Dry Vacuum Graphite Machining Center.

Discover the power of the DC6060G for yourself. Contact our sales team today and let us help you find the perfect solution for your graphite machining needs. Say goodbye to dust and metal shavings problems and hello to a more efficient and profitable future!