The graphite machining industry has long faced challenges related to dust accumulation and metal chip corrosion, which significantly impact both machine performance and operator safety. Traditional machining centers often struggle with these issues, leading to increased maintenance costs, reduced tool life, and lower production efficiency. However, the DC6060G Wet Flush Graphite Machining Center offers a revolutionary solution that addresses these pain points head-on.

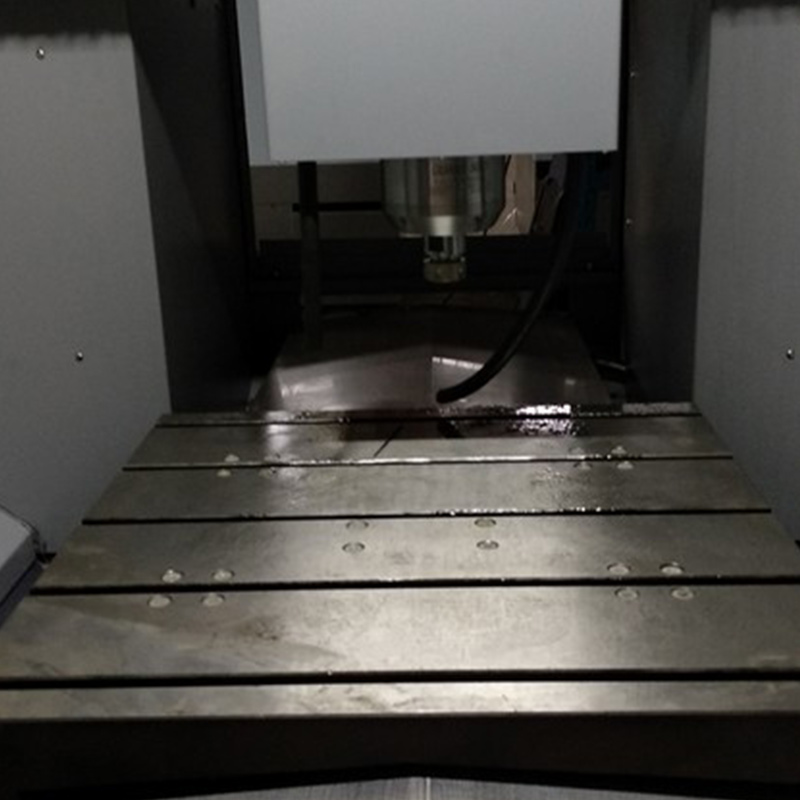

Building upon the proven design of the DC6060A CNC Milling Machine, the DC6060G introduces a series of advanced features tailored specifically for graphite processing. One of its most notable innovations is the fully sealed enclosure, which provides robust protection for internal components and electronic systems. This design not only enhances the machine's durability but also creates a cleaner, safer working environment.

In addition to the sealed structure, the DC6060G integrates a wet flushing system that effectively removes graphite dust in real-time. Unlike dry machining methods, where fine particles can settle on sensitive parts and cause long-term damage, this wet system ensures continuous cleanliness, maintaining optimal cutting conditions throughout the process.

One of our valued clients, a leading manufacturer of graphite electrodes for the semiconductor industry, reported a significant improvement in productivity after switching to the DC6060G. Before implementation, their traditional machines were plagued by frequent downtime due to dust buildup and corrosion. After adopting the DC6060G, they saw a 35% increase in machining efficiency and a 40% reduction in maintenance costs.

“The wet flushing system made a world of difference,” said the client’s production manager. “We no longer have to stop the machine to clean it manually, and the overall quality of our products has improved dramatically.”

The DC6060G is designed to deliver exceptional performance in high-volume graphite machining applications. Below are some of its key benefits:

| Feature | Benefit |

|---|---|

| Fully Sealed Enclosure | Protects internal components from dust and moisture |

| Wet Flushing System | Removes graphite dust in real-time, reducing downtime |

| High Precision Cutting | Ensures consistent product quality and dimensional accuracy |

| Longer Tool Life | Reduces wear and tear on cutting tools |

The DC6060G is more than just an upgrade—it's a game-changer for any business involved in graphite machining. With its combination of advanced design, reliable performance, and proven results, it stands out as a top choice in the market. Whether you're looking to reduce operational costs, improve product quality, or extend machine lifespan, the DC6060G delivers on all fronts.

Don’t miss the opportunity to transform your graphite machining operations. Take the next step today and discover how the DC6060G can elevate your production capabilities.

Get a Free Product Consultation Now