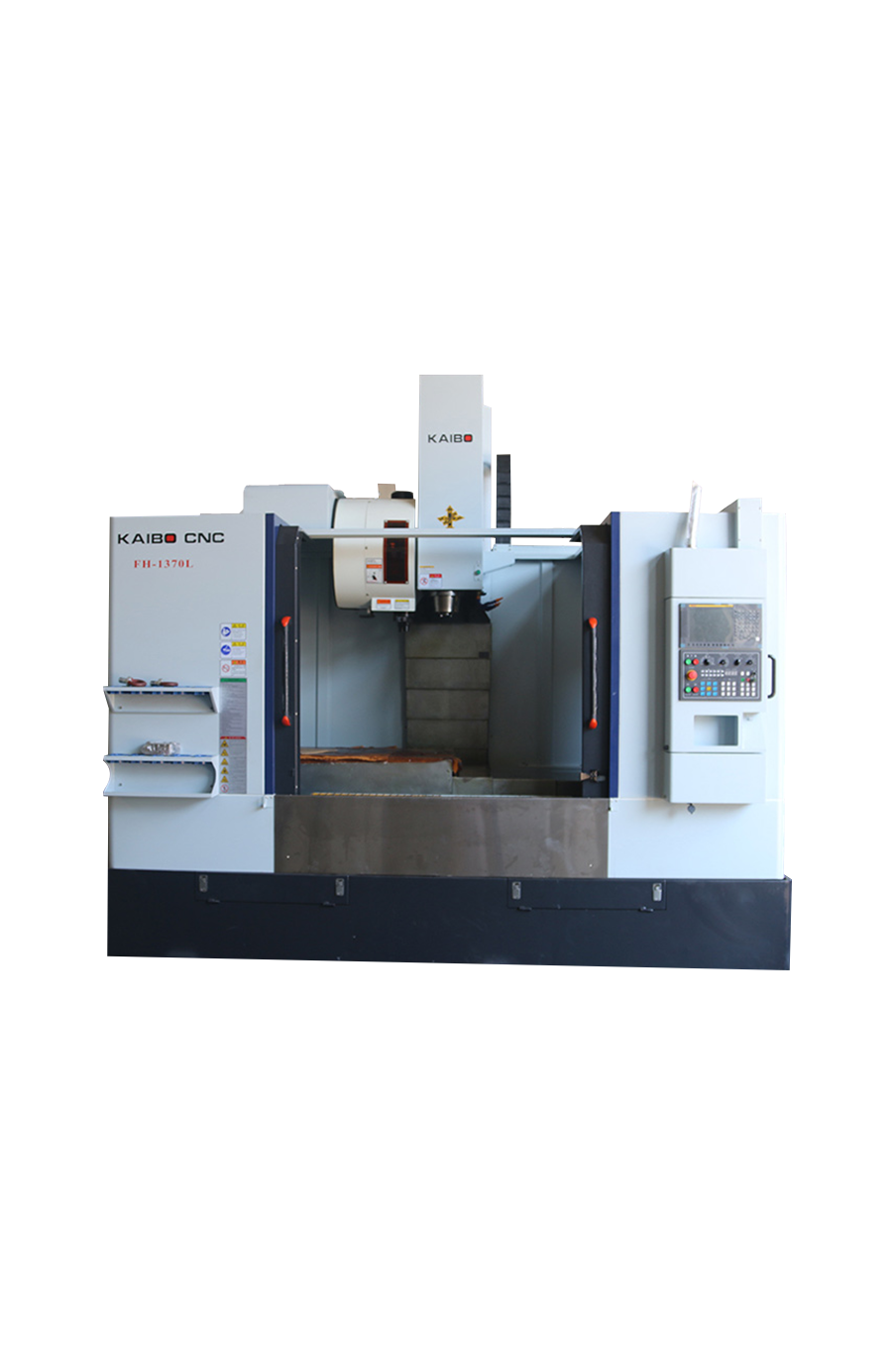

In the world of manufacturing, particularly in the machining of materials like graphite, achieving higher efficiency and precision is paramount. The FH1370L CNC milling machine stands out as a formidable solution to address the persistent industry challenges faced by manufacturers. This case study delves into the pain points of graphite machining and highlights how the FH1370L can significantly enhance machining efficiency.

Graphite machining presents unique challenges that can hinder productivity. Some common challenges include:

The FH1370L CNC milling machine is specifically designed to tackle these challenges head-on. Here’s how it makes a difference:

Equipped with advanced servo motors and superior controls, the FH1370L ensures high precision and repeatability in machining operations, significantly improving overall product quality.

The machine allows for optimized cutting speed and feed rates, reducing heat generation and extending tool life, which leads to lower production costs.

The integrated cooling systems effectively manage temperature during machining, maintaining tool integrity and ensuring superior surface finishes.

In conclusion, the FH1370L CNC milling machine emerges as a comprehensive solution for the graphite machining industry, efficiently addressing the pain points faced by manufacturers. By adopting this innovative machine, businesses can significantly enhance their machining processes, meet modern production demands, and ultimately boost their bottom line.

Image of FH1370L CNC Milling Machine