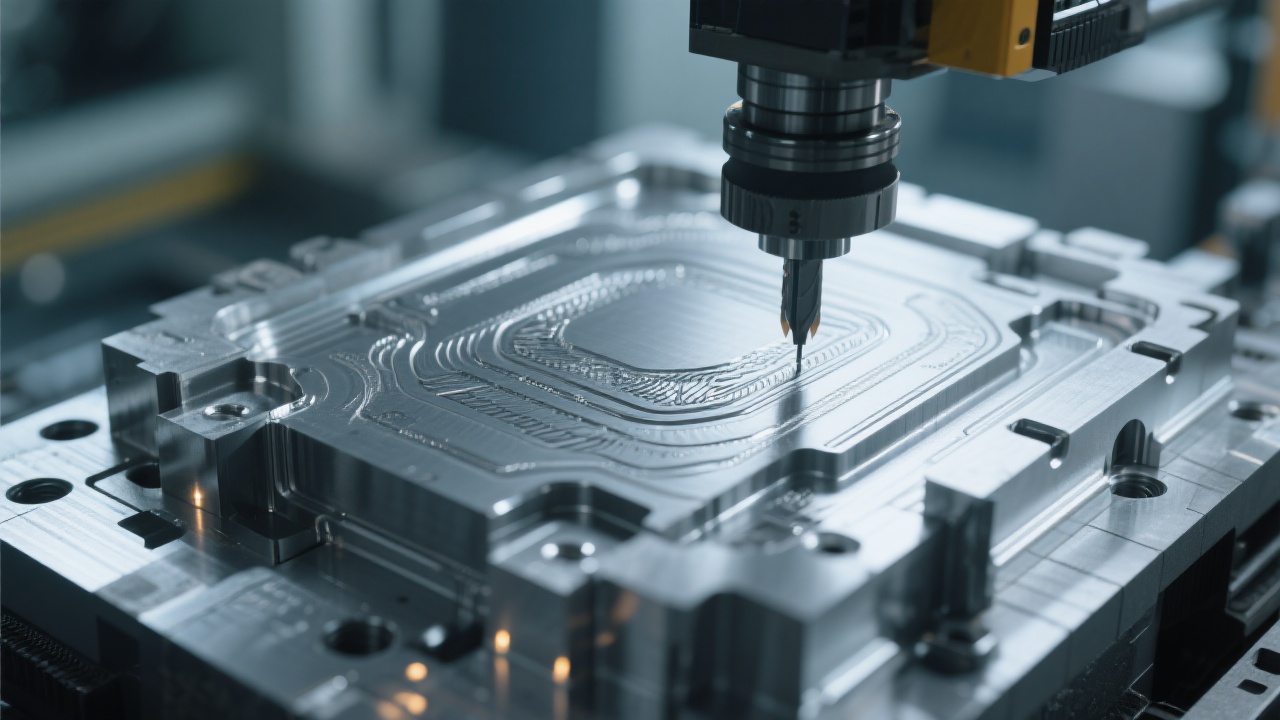

In today’s global manufacturing landscape, mold makers face relentless pressure to reduce cycle times while maintaining precision — especially in industries like automotive, aerospace, and consumer electronics. That’s where the FANUC GV2030 Heavy-Duty Machining Center steps in as a game-changer.

The GV2030 isn’t just another CNC machine — it's a double-column, large-travel milling system engineered for stability under heavy load. With a maximum travel of 4,000 mm X-axis, 2,000 mm Y-axis, and 1,500 mm Z-axis, it handles oversized molds and complex parts with ease. Its thermal compensation system ensures consistent accuracy within ±0.01 mm over 8 hours of continuous operation — a critical metric for mold shops that can't afford dimensional drift.

| Feature | Standard Value | Industry Benchmark |

|---|---|---|

| Max Travel (X/Y/Z) | 4,000 / 2,000 / 1,500 mm | ~3,000 / 1,500 / 1,000 mm |

| Positioning Accuracy | ±0.01 mm | ±0.03 mm |

| Spindle Speed | 12,000 RPM | 8,000–10,000 RPM |

Take the case of a German Tier-1 auto supplier who switched from a legacy gantry mill to the GV2030. Their average mold production time dropped from 72 hours to 48 hours — a 33% gain — without sacrificing surface finish or tolerance control. In aerospace, a U.S.-based component manufacturer reported a 40% reduction in scrap rates after integrating GV2030 into their die-casting mold workflow, thanks to its superior vibration damping and toolpath optimization capabilities.

And it’s not just about speed — reliability matters too. One customer in Japan said: “We’ve run this machine 24/7 for over 18 months now, and we haven’t had a single unplanned downtime due to mechanical failure.” That kind of uptime translates directly into ROI.

Whether you're producing engine blocks for diesel vehicles or intricate plastic injection molds for home appliances, the GV2030 adapts to your workflow — not the other way around. Its robust structure supports heavy cuts, while the integrated FANUC controller delivers smooth motion even during multi-axis simultaneous operations.

Here’s what most buyers overlook: the GV2030 doesn’t just do more — it does better. While many competitors focus on raw power, FANUC prioritizes repeatability, thermal stability, and operator-friendly interfaces. For example, the built-in diagnostics allow predictive maintenance alerts — meaning fewer surprises and smoother production planning.

Think of it this way: if your current setup is limiting your growth because of inconsistent finishes or long lead times, the GV2030 could be the missing piece to scale efficiently across multiple markets.

If you’re serious about improving throughput, reducing defects, and future-proofing your shop floor, the FANUC GV2030 deserves your attention.