In the era of rapid technological advancement, the manufacturing industry is facing unprecedented challenges and opportunities. Factory upgrade and transformation have become urgent tasks for many manufacturers. This article will delve into how the FANUC GV2030 Heavy-duty Machining Center can play a crucial role in this process.

Manufacturers often encounter efficiency and cost challenges during the upgrade and transformation process. According to industry research, nearly 60% of factories struggle with low production efficiency, which leads to high costs and reduced competitiveness. For example, in traditional manufacturing processes, long setup times and limited machining flexibility often result in wasted time and resources. These pain points have severely restricted the development of the manufacturing industry.

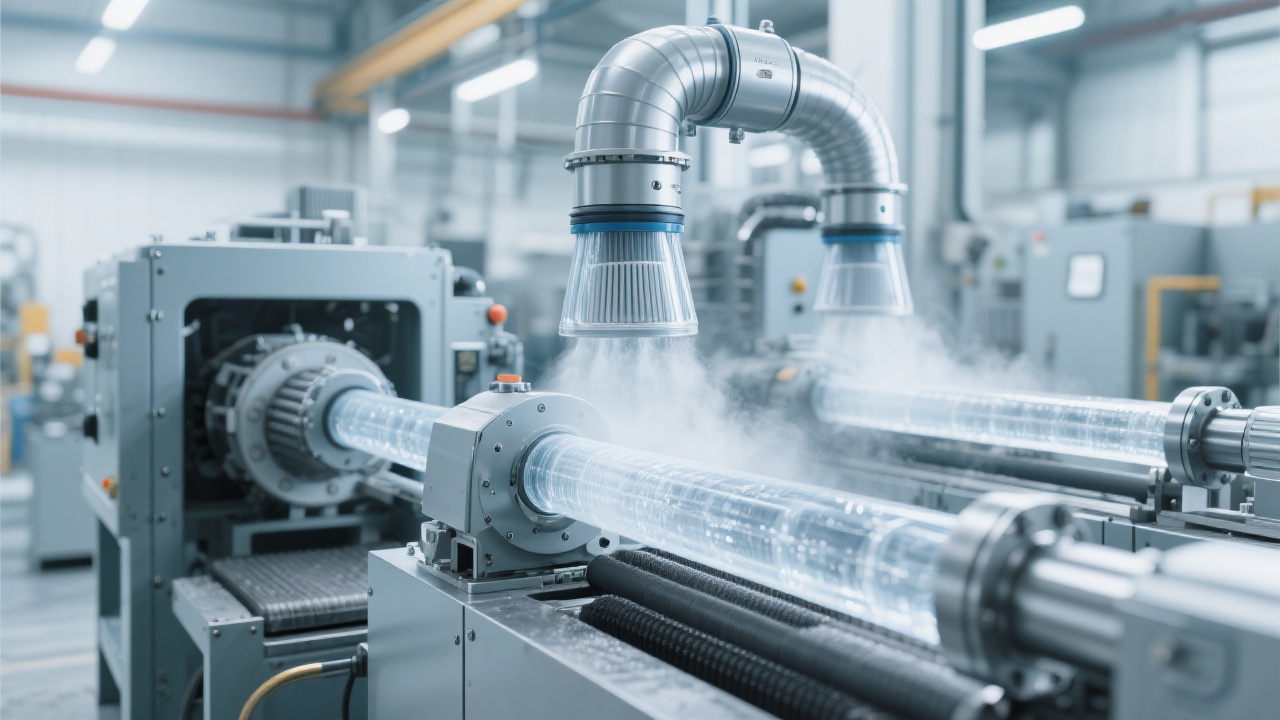

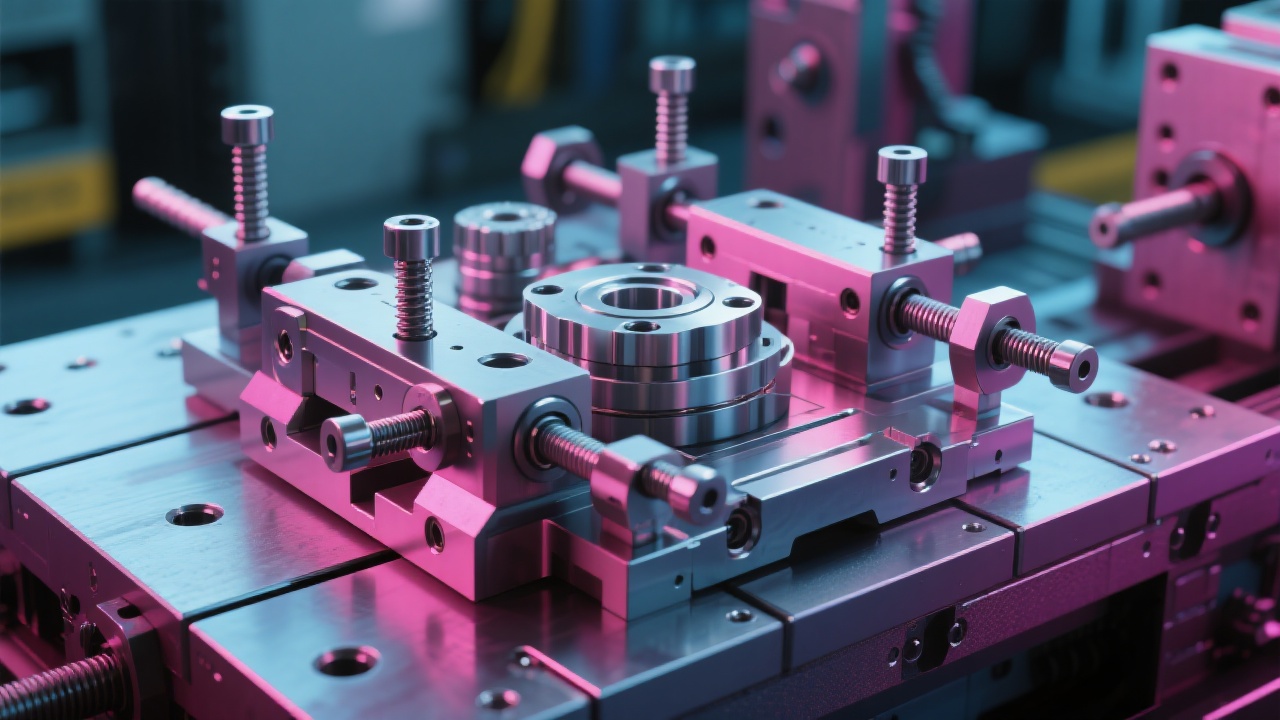

The FANUC GV2030 Heavy-duty Machining Center, as a double-column large-travel high-precision CNC milling machine, has several outstanding core advantages. First of all, its large travel allows it to handle workpieces of various sizes, which is very suitable for large-scale production. With a travel range of up to [X mm] in the X-axis, [Y mm] in the Y-axis, and [Z mm] in the Z-axis, it can easily accommodate large and complex workpieces.

Secondly, its high precision ensures the quality of the machined products. The positioning accuracy can reach ±[X] mm, and the repeat positioning accuracy is ±[X] mm. This high precision is crucial for industries with strict quality requirements, such as aerospace and automotive parts manufacturing.

Most importantly, the FANUC GV2030 can flexibly adjust the machining plan. Through advanced CNC systems and intelligent control algorithms, it can quickly adapt to different production requirements, reducing setup times and improving production efficiency.

The FANUC GV2030 Heavy-duty Machining Center is widely applicable in multiple fields. In the automotive parts manufacturing industry, it can be used to machine engine blocks, transmission cases, and other key components. In the aerospace industry, it can handle complex parts such as turbine blades and structural components. In the mold manufacturing industry, it can efficiently produce high-precision molds.

Let's take a look at a real case. A well - known automotive parts manufacturer introduced the FANUC GV2030 Heavy-duty Machining Center. After using it for one year, the production efficiency increased by 30%, and the production cost decreased by 20%. This shows that the FANUC GV2030 can bring significant economic benefits to enterprises.

The FANUC GV2030 Heavy-duty Machining Center is not only a high - performance machining device but also a key tool for factories to achieve intelligent and efficient production. By integrating with advanced manufacturing execution systems (MES) and the Internet of Things (IoT), it can realize real - time monitoring of the production process, predictive maintenance, and intelligent scheduling.

For example, through IoT sensors, the machine can collect data on its operating status, such as temperature, vibration, and power consumption. This data can be analyzed to predict potential failures in advance, reducing unplanned downtime and maintenance costs.

We encourage you to share your questions and experiences in the comments section below. Whether you are a factory manager, a production engineer, or a decision - maker, your opinions are very important to us.

Are you ready to take your factory to the next level with the FANUC GV2030 Heavy-duty Machining Center? Click here to learn more and start your upgrade journey today!