As the demand for high-precision graphite processing continues to grow across industries such as aerospace, automotive, and electronics, manufacturers are increasingly seeking reliable solutions that ensure both equipment longevity and environmental cleanliness. The DC6060G Wet-Flush Graphite Machining Center stands out in this market with its innovative full-sealed hood design and advanced wet-flush system, effectively addressing common challenges in graphite machining.

Graphite machining generates a significant amount of fine dust and metal shavings, which can easily accumulate inside machine tools, leading to corrosion, reduced precision, and shortened service life. Traditional machining centers often lack sufficient protection against these contaminants, resulting in frequent maintenance and downtime.

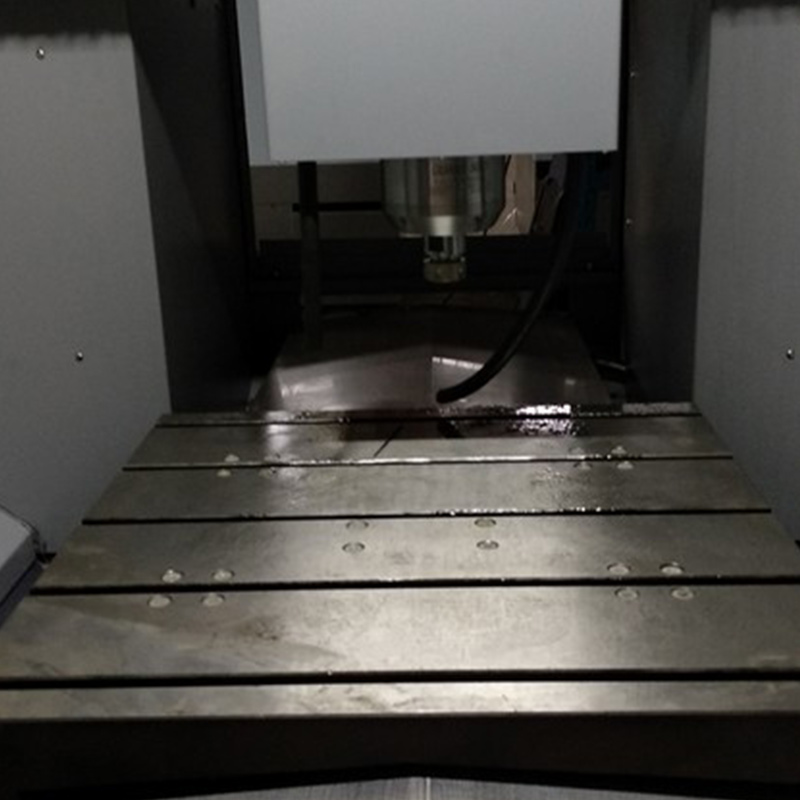

The DC6060G is designed to overcome these issues by incorporating a fully enclosed hood that acts as a barrier between the machining area and sensitive components. This design not only contains the debris but also prevents it from entering critical areas of the machine, ensuring consistent performance and reducing long-term maintenance costs.

The wet-flush system in the DC6060G plays a crucial role in maintaining a clean and efficient machining environment. By continuously flushing away graphite dust and metal chips, it ensures that the cutting area remains free from contamination, which is essential for achieving high-precision results.

Compared to traditional dry machining methods, the wet-flush system significantly reduces airborne particulates, improving workplace safety and overall air quality. According to internal testing, the system can reduce dust levels by up to 85%, making it an ideal solution for environments where cleanliness is a priority.

| Feature | Traditional Machine | DC6060G |

|---|---|---|

| Dust Containment | Limited | Full Sealed Hood |

| Dust Removal | Manual or Inefficient | Automatic Wet-Flush System |

| Maintenance Frequency | High | Low |

One of our valued customers, a leading manufacturer in the aerospace industry, reported a 70% reduction in machine downtime after switching to the DC6060G. They highlighted the effectiveness of the sealed hood and wet-flush system in keeping their production lines running smoothly without frequent cleaning or repairs.

"The DC6060G has transformed our graphite machining process," said a production manager. "We’ve seen a marked improvement in both product quality and equipment reliability."

With its full-sealed hood design and advanced wet-flush system, the DC6060G offers a comprehensive solution to the challenges of graphite machining. It not only protects your equipment from damage but also improves working conditions and enhances productivity.

Are you looking for a reliable and efficient graphite machining center that meets the highest standards of performance and cleanliness? Discover how the DC6060G can benefit your operations today.