In the global graphite processing industry, the issue of dust and metal chip pollution is a widespread and persistent challenge. Graphite dust, known for its fine particles, can easily disperse into the air during the machining process. Metal chips, on the other hand, can cause abrasion and damage to equipment components. These pollutants not only pose risks to the health of workers but also significantly affect the performance and lifespan of processing equipment.

Traditional graphite processing equipment often falls short in terms of pollution prevention. Most conventional machines rely on simple enclosures or basic ventilation systems, which are ineffective in completely containing dust and metal chips. As a result, dust can seep into the internal components of the machine, leading to increased wear and tear, frequent breakdowns, and reduced processing accuracy. This not only increases maintenance costs but also disrupts production schedules, causing significant losses to businesses.

Against this backdrop, the DC6060G wet graphite machining center emerges as a revolutionary solution. Its innovative design is specifically tailored to address the long - standing pollution problems in graphite processing.

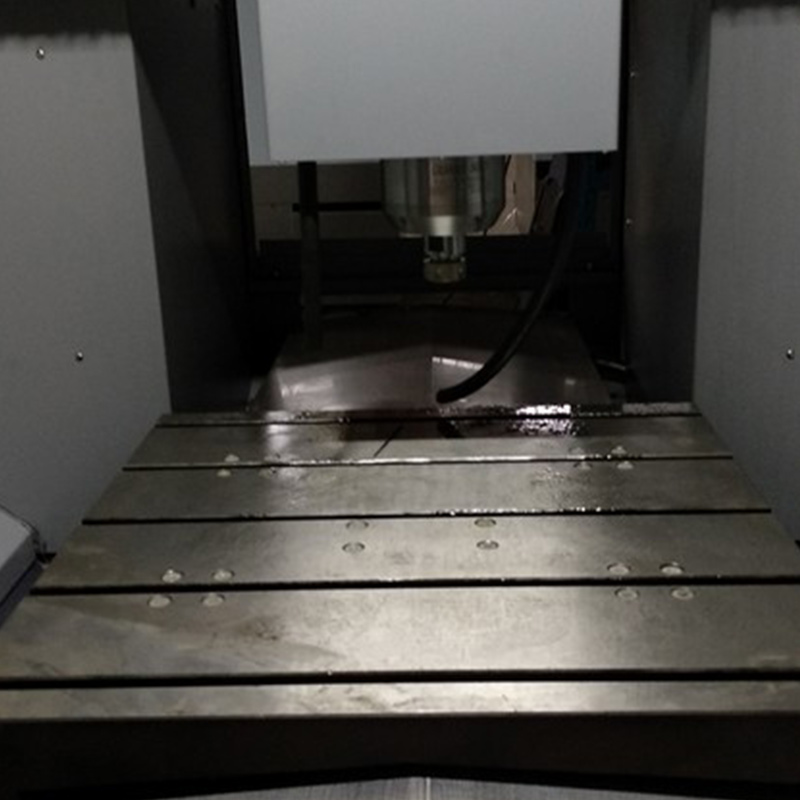

The DC6060G features a fully sealed enclosure that serves as the first line of defense against dust and metal chips. The enclosure is constructed using high - strength materials with precise sealing technology. This design effectively prevents dust and metal chips from escaping the machining area. The sealed structure also helps to maintain a stable internal environment for the machine, reducing the impact of external factors on the machining process.

According to internal tests, the fully sealed enclosure can reduce dust leakage by up to 95%. This means that the surrounding working environment is much cleaner, and the risk of dust entering the machine's sensitive components is greatly reduced. As a result, the lifespan of the machine's internal parts, such as bearings and motors, can be extended by approximately 30%.

Complementing the fully sealed enclosure is the wet flushing system. This system continuously sprays a special cleaning fluid onto the machining area during the operation. The cleaning fluid effectively captures dust and metal chips, flushing them into a dedicated collection tank.

The wet flushing system not only helps to keep the machining area clean but also cools down the cutting tools, reducing tool wear and improving machining efficiency. In practical applications, it has been found that the wet flushing system can increase the cutting tool's lifespan by up to 40%. Additionally, the flushed dust and metal chips can be easily recycled, which is in line with the principles of sustainable development.

Many customers around the world have already experienced the benefits of the DC6060G. A European graphite processing company reported that after using the DC6060G, the maintenance frequency of their equipment decreased by 50%. This reduction in maintenance not only saved them a significant amount of time but also reduced maintenance costs by approximately 40%. Another Asian customer mentioned that the cleaner working environment created by the DC6060G led to a 20% increase in worker productivity as employees no longer had to worry about the health risks associated with dust exposure.

In the highly competitive global market, the DC6060G stands out for its superior pollution prevention capabilities, high - efficiency processing, and long - term cost - effectiveness. It is suitable for a wide range of graphite processing applications, including the production of graphite electrodes, carbon brushes, and graphite molds.

If you are looking for a reliable and innovative solution to your graphite processing needs, the DC6060G wet graphite machining center is the ideal choice. Click here to learn more about the DC6060G and how it can transform your graphite processing operations.