In the aerospace industry, the demand for high-precision machining equipment is extremely high. Since aerospace parts are often complex in shape and have strict requirements for dimensional accuracy and surface quality, a high-performance machining center is essential. The FANUC GV2030 double-column large-travel CNC milling machine stands out in this regard. Its high stability is one of its core advantages. The double-column structure design provides a solid support foundation for the machine tool, effectively reducing vibration during the machining process. For example, in high-speed milling operations, the vibration amplitude can be controlled within 0.01mm, which is far lower than the industry average of 0.03mm, ensuring the stability of the machining process and the accuracy of the parts.

In addition to high stability, the FANUC GV2030 also has excellent production efficiency. It is equipped with a high-power spindle motor and an advanced control system, which can achieve rapid tool changes and high-speed feed. The tool change time is only 2 seconds, while the average tool change time of similar products in the market is about 3 - 4 seconds. The maximum feed speed can reach 60m/min, which greatly shortens the machining cycle and improves production efficiency.

Let's take a look at the practical application of the FANUC GV2030 in the aerospace industry. An aerospace manufacturing company used to use traditional machining equipment to process complex structural parts, and the machining accuracy was only about ±0.05mm. After replacing it with the FANUC GV2030, the machining accuracy was improved to ±0.01mm, and the surface roughness Ra value was reduced from 3.2μm to 0.8μm, which fully met the high-precision requirements of aerospace parts. Moreover, the production efficiency was increased by 30%, and the production cost was reduced by 20% due to the reduction of scrap rate and the shortening of the machining cycle.

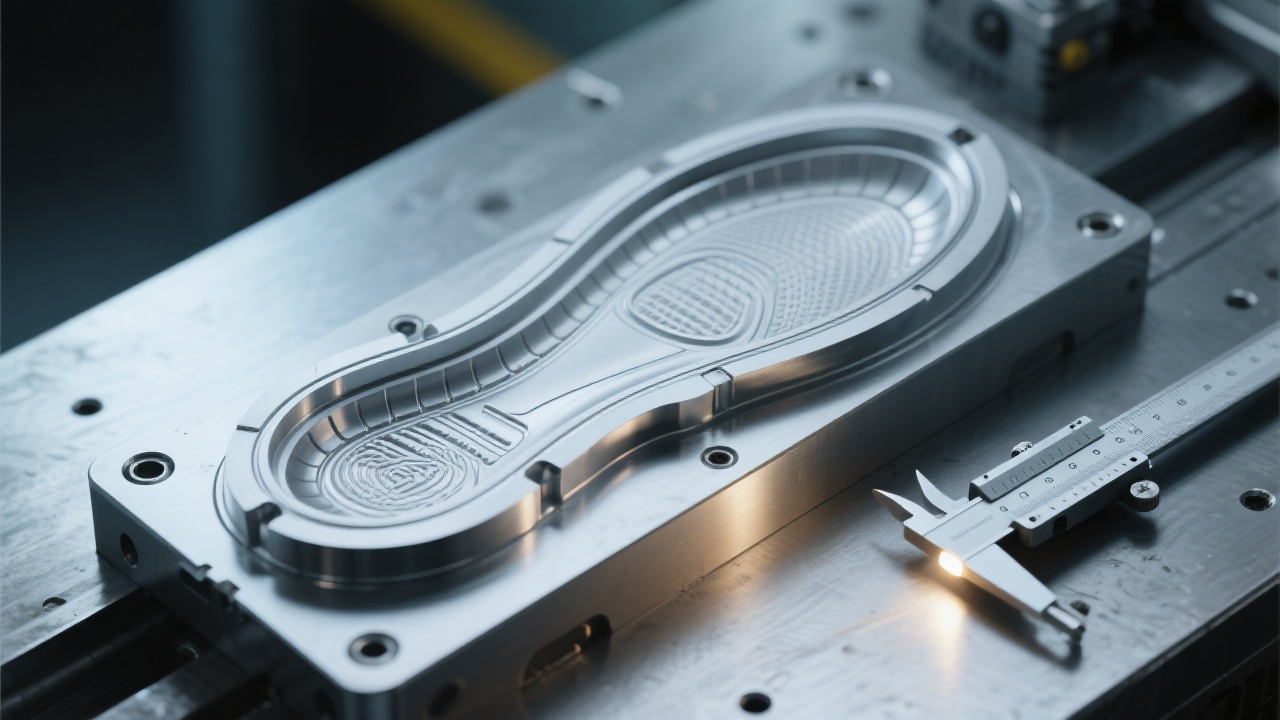

The FANUC GV2030 is not only widely used in the aerospace industry but also has excellent performance in other industries. In the automotive parts manufacturing industry, a company used the FANUC GV2030 to process engine cylinder heads. The machining accuracy was improved, and the production efficiency was increased by 25%. In the mold manufacturing industry, a mold factory used this machine tool to process complex molds, and the mold surface quality was significantly improved, and the mold production cycle was shortened by 35%.

| Industry | Original Situation | After Using FANUC GV2030 |

|---|---|---|

| Aerospace | Accuracy ±0.05mm, Surface roughness Ra 3.2μm, Efficiency low | Accuracy ±0.01mm, Surface roughness Ra 0.8μm, Efficiency increased by 30% |

| Automotive Parts | Accuracy general, Efficiency normal | Accuracy improved, Efficiency increased by 25% |

| Mold Manufacturing | Long production cycle, General surface quality | Production cycle shortened by 35%, Surface quality significantly improved |

Customers who have used the FANUC GV2030 have given high evaluations. A customer from the aerospace industry said, "The FANUC GV2030 has completely changed our production mode. Its high precision and high efficiency have helped us win more high - end orders, and we are very satisfied with it." Another customer from the mold manufacturing industry also mentioned, "This machine tool has excellent performance and stability. It has greatly improved our mold quality and production efficiency, and it is really a good helper in our production process."

In conclusion, the FANUC GV2030 double - column large - travel CNC milling machine has significant advantages in improving production efficiency and processing quality. Whether in the aerospace industry or other industries, it can play a huge role. If you are also looking for a high - performance machining center to optimize your production process and enhance your market competitiveness, click here to learn more about the FANUC GV2030.