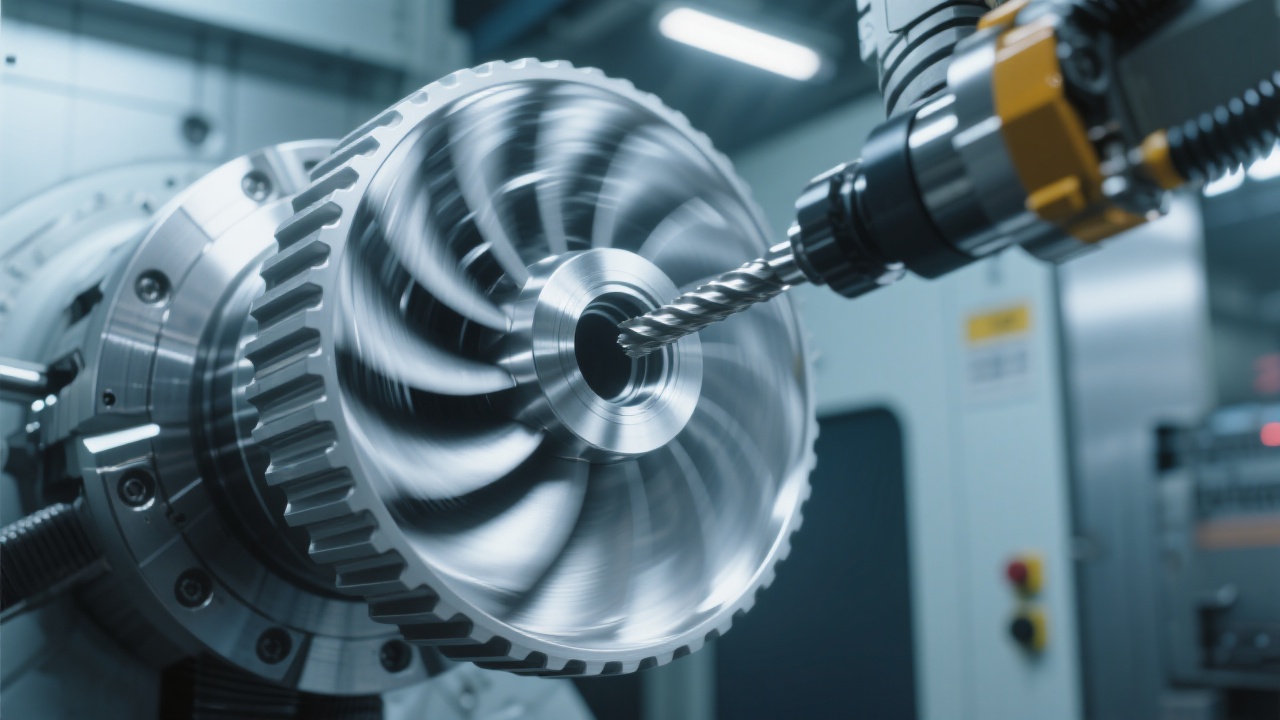

In the dynamic landscape of modern manufacturing, the pursuit of efficiency and precision is unceasing. The automotive parts industry, in particular, demands high - performance equipment to keep up with the ever - increasing production requirements. Enter the GV2040, a double - column large - stroke CNC milling machine that is revolutionizing the way automotive parts are processed.

The GV2040 stands out with its remarkable structural design. Its large worktable, with dimensions that can accommodate large - scale automotive parts, provides a stable foundation for machining. This design reduces vibration during the machining process, ensuring high - precision operations. For example, it can handle workpieces up to [X] cubic meters, which is significantly larger than many similar machines in the market.

The core function of the GV2040 is powered by advanced CNC control systems. These systems allow for precise control of the cutting tools, enabling multi - axis machining. This means that complex automotive parts, such as engine blocks and transmission components, can be machined in a single setup, reducing the time and cost associated with multiple setups. In fact, compared to traditional milling machines, the GV2040 can reduce the machining time for certain automotive parts by up to [X]%.

While the automotive industry is a major beneficiary, the GV2040's versatility extends to other sectors as well. In the aerospace industry, where precision and reliability are of utmost importance, the GV2040 can machine critical components with tight tolerances. For instance, it can achieve a machining accuracy of ±[X] mm, which meets the strict requirements of aerospace applications.

In the mold manufacturing industry, the GV2040's ability to perform high - speed and high - precision machining makes it an ideal choice. It can quickly produce complex mold cavities, reducing the lead time for mold production. In the engine manufacturing and home appliance industries, the machine's large - stroke and high - power capabilities enable efficient production of various components.

Let's take a look at some real - world examples. A leading automotive parts manufacturer implemented the GV2040 in their production line. Within the first three months, they noticed a [X]% increase in production efficiency and a [X]% improvement in product quality. Defects were significantly reduced, leading to cost savings and improved customer satisfaction.

Another company in the aerospace sector reported that the GV2040 helped them reduce the production time for a particular component from [X] hours to [X] hours. This not only increased their production capacity but also allowed them to take on more orders.

For manufacturing decision - makers, the GV2040 offers a compelling value proposition. By investing in this machine, companies can expect a significant return on investment. The increased production efficiency means more products can be produced in less time, leading to higher revenues. The improved product quality reduces the cost of rework and customer complaints, enhancing the company's reputation in the market.

Moreover, the GV2040's multi - industry applicability provides flexibility. Companies can use the machine to diversify their product offerings, entering new markets and expanding their business.

If you're looking to take your manufacturing operations to the next level, the GV2040 is the solution you've been waiting for. Don't miss out on this opportunity to enhance your efficiency and quality. Click here to learn more and request a product trial today!