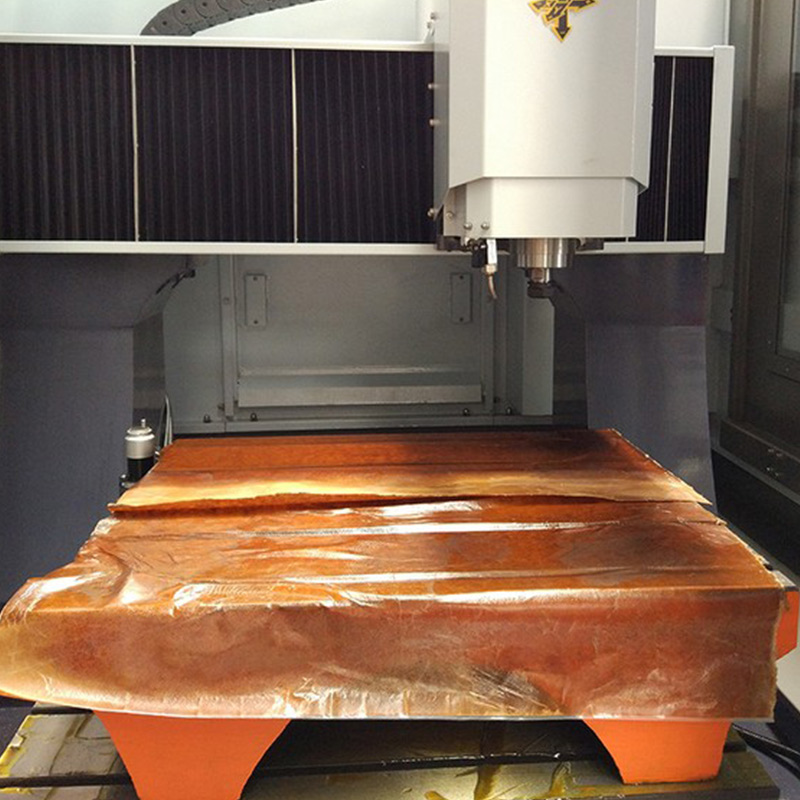

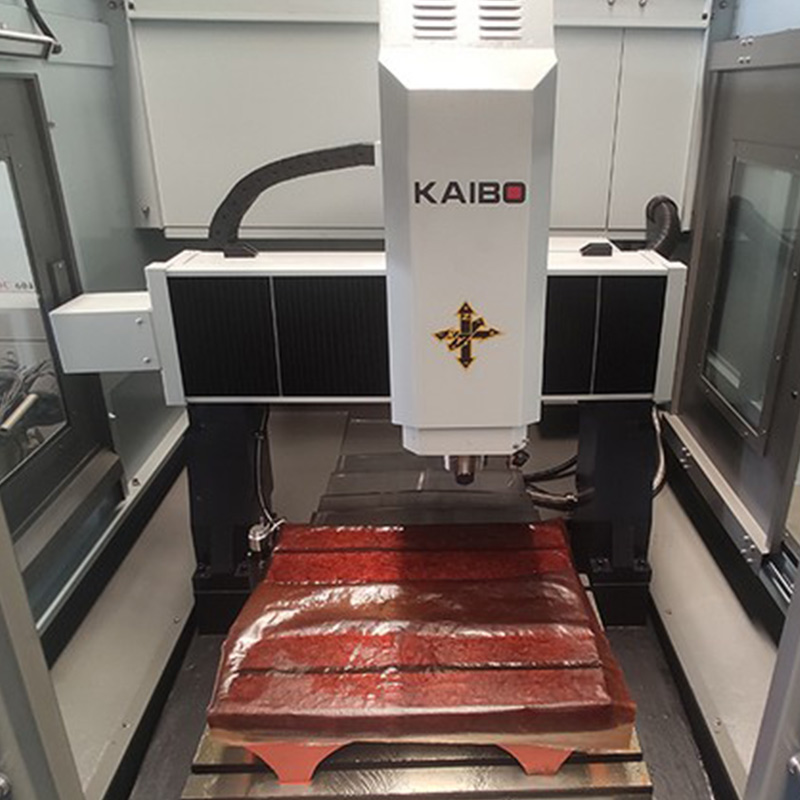

In today’s competitive manufacturing landscape, precision and adaptability are paramount. The GJ1417 stainless steel CNC milling machine emerges as a leading solution, offering unparalleled accuracy, robust construction, and intelligent control designed to meet the evolving needs of various industries. From aerospace components to medical instruments, this cutting-edge equipment empowers manufacturers to achieve exceptional results with greater efficiency.

At the core of the GJ1417’s reliability lies its premium-grade stainless steel framework. Engineered with high-strength alloy steel treated through advanced surface-hardening techniques, the machine guarantees enhanced rigidity and longevity under demanding conditions. This not only ensures minimal deformation during high-speed operation but also resists corrosion, an essential factor for industries such as chemical processing and food manufacturing where exposure to harsh environments is common.

| Feature | Specification | Industry Benefit |

|---|---|---|

| Material | SUS 304/316 Stainless Steel Alloy | Resists corrosion, extends machine lifespan |

| Surface Treatment | Cryogenic tempering for hardness above HRC 55 | Improved wear resistance for consistent precision |

| Frame Design | Optimized for vibration dampening and thermal stability | Maintains accuracy even in continuous operations |

The GJ1417 integrates an industry-leading CNC control system with embedded automatic programming capabilities and real-time process monitoring. This intelligent system minimizes human error, accelerates setup times by up to 35%, and continuously optimizes operational parameters to ensure consistent machining quality.

Key capabilities include adaptive tool path adjustment based on live sensor feedback, predictive maintenance alerts to reduce unplanned downtime, and seamless integration with industry 4.0 networks for comprehensive data tracking. The user-friendly interface supports multi-language input, simplifying adoption in international production environments.

The true testament of the GJ1417’s value shines through its versatility across multiple sectors:

Each application underscores the GJ1417’s flexibility to process various workpiece shapes and sizes, from simple flat panels to intricate 3D forms, without compromising cycle times or dimensional consistency.

When compared to other stainless steel CNC milling machines in the market, the GJ1417 stands out due to its holistic blend of innovation and engineering precision:

| Aspect | GJ1417 | Typical Competitor |

|---|---|---|

| Material Quality | High-grade SUS 304/316 with cryogenic tempering | Standard stainless steel alloys without enhanced treatment |

| CNC System Intelligence | Adaptive programming & predictive maintenance | Manual programming with limited monitoring |

| Precision Accuracy | ±0.01 mm | ±0.03 mm or higher |

| Industry Certifications | ISO 9001, CE, RoHS compliant | Partial or no certifications |

Industry feedback confirms that adopting the GJ1417 can enhance production throughput by up to 25% while reducing material waste due to its precise milling capabilities. This translates to significant cost savings and faster time-to-market for component manufacturers.

Take, for example, a leading medical device manufacturer who integrated the GJ1417 into their workflow: setup times decreased by 40%, enabling faster batch customization for orthopedic implants while maintaining a consistent tolerance of ±0.008 mm. Such operational efficiencies establish a competitive advantage in sectors where quality and speed are inseparable.

Are you ready to elevate your production capabilities with the GJ1417 stainless steel CNC milling machine? Discover how this innovative solution can adapt to your unique machining challenges and deliver superior results.

Explore the GJ1417 CNC Milling Machine Capabilities Now

We invite your questions and insights — leave a comment below or contact our technical team to discuss how the GJ1417 can optimize your production line.