In the demanding field of graphite machining, maintaining precision while controlling environmental hazards such as dust and contamination is a perennial challenge. The DC6060G Wet Graphite Machining Center emerges as a technologically advanced solution engineered to address these industry challenges. Building upon the proven CNC milling technology of its predecessor, the DC6060A, the DC6060G integrates state-of-the-art innovations including a fully sealed enclosure and an advanced wet flushing system. These features collectively elevate its operational efficiency, durability, and workplace safety, positioning it as a leading choice for global procurement specialists seeking dependable graphite processing equipment.

Graphite machining environments face two critical operational hurdles: excessive dust generation and equipment wear from highly abrasive particles. These issues often lead to frequent maintenance downtimes, compromised worker health, and diminished product quality. Traditional dry machining setups fall short in mitigating these risks, prompting the demand for specialized, dust-controlled solutions. The DC6060G directly responds to these demands by utilizing wet machining technology, which significantly suppresses airborne particulates and provides continuous cooling.

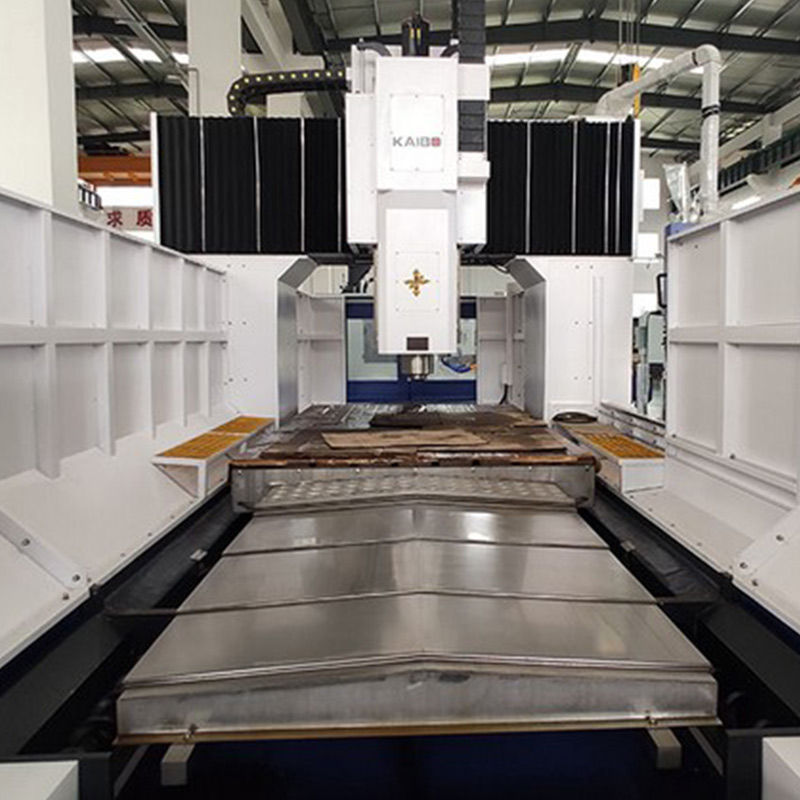

The DC6060G inherits the robust CNC infrastructure, accuracy, and programmability of the DC6060A milling platform, renowned for its structural rigidity and precision control. Through targeted design enhancements, the DC6060G surpasses its predecessor by integrating:

| Technical Parameter | DC6060A | DC6060G |

|---|---|---|

| Spindle Speed (rpm) | 12,000 | 15,000 |

| Maximum Workpiece Size (mm) | 600 × 600 × 300 | 600 × 600 × 300 |

| Enclosure Type | Open | Fully Sealed |

| Dust Control Method | Dry | Wet Flushing System |

| Average Processing Cycle Time (min) | 45 | 35 |

The DC6060G's fully sealed enclosure creates a controlled atmosphere that traps particulate matter generated during graphite milling, preventing contamination of both the machine’s internal structure and surrounding environment. Simultaneously, the wet flushing system channels coolant and deionized water in a continuous flow over the machining zone. This dual mechanism:

Leading graphite component manufacturers across Asia and Europe have reported measurable improvements after integrating the DC6060G into their production lines:

The DC6060G represents a strategic blend of time-tested CNC milling reliability and forward-thinking environmental technology. By addressing critical pain points such as dust pollution and equipment wear, it delivers operational excellence that is both measurable and sustainable. Its proven capacity to enhance productivity by up to 25%, reduce equipment lifecycle costs, and meet stringent workplace environmental standards makes the DC6060G an indispensable asset for any enterprise specializing in graphite processing.

Equip your production facility with an industry-leading solution that combines precision, durability, and environmental responsibility. Discover how the DC6060G can elevate your machining operations—contact our experts today for a personalized consultation and detailed performance data tailored to your production needs.