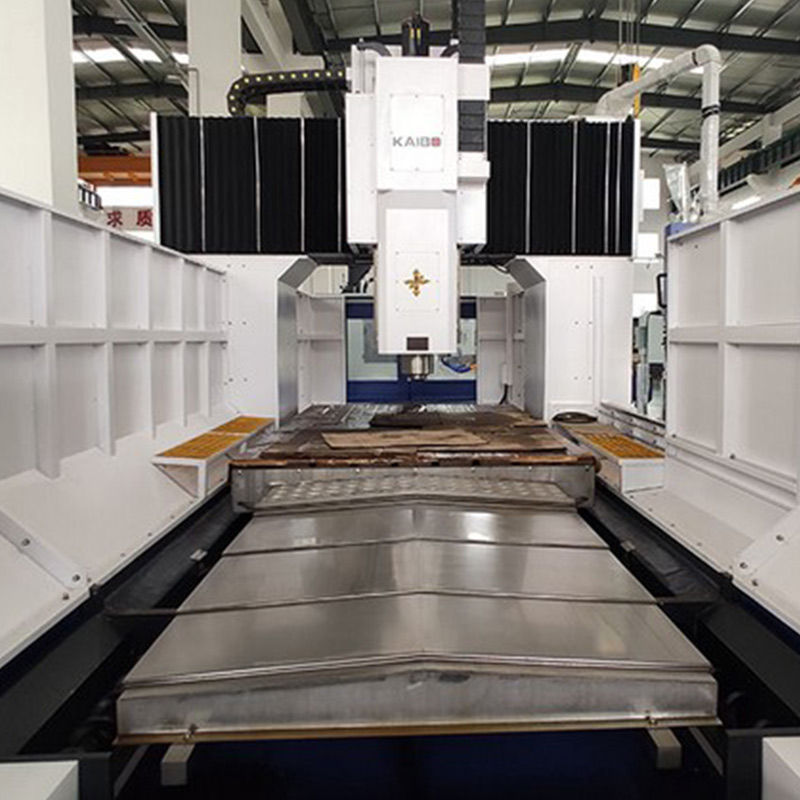

The DC1090A Wheel CNC Milling Machine, equipped with a BT40 spindle, has emerged as a game-changer in the precision machining industry. This article delves into the market competitiveness of the machine by analyzing real customer experiences and comparing it with traditional vertical machining centers. The focus is on how this machine meets the evolving demands of the manufacturing sector, particularly in product engraving and mold processing.

According to recent market research, global manufacturers are increasingly seeking machines that offer high precision, reliability, and efficiency. In particular, the demand for specialized equipment tailored for wheel machining and complex mold production has seen a significant rise. The DC1090A aligns perfectly with these needs, offering advanced features that traditional vertical machining centers struggle to match.

| Feature | DC1090A (BT40 Spindle) | Traditional Vertical Machining Center |

|---|---|---|

| Spindle Speed | 12,000 RPM | 8,000 RPM |

| Positioning Accuracy | ±0.005 mm | ±0.01 mm |

| Repeatability | ±0.003 mm | ±0.007 mm |

One of our long-term clients, a leading automotive parts manufacturer in Germany, reported a 35% increase in productivity after switching to the DC1090A. “The machine's stability and precision have significantly reduced our tool wear and rework time,” said their production manager. Another customer in the footwear industry noted that the DC1090A improved their mold production process by 40%, allowing them to meet tight deadlines more effectively.

The DC1090A’s BT40 spindle provides enhanced rigidity and torque, making it ideal for heavy-duty machining tasks. Its advanced control system ensures smooth operation even under demanding conditions. For customers who require high-precision work in product engraving or mold manufacturing, the DC1090A offers a reliable and scalable solution.

“We were skeptical at first, but the performance of the DC1090A exceeded our expectations,” shared a customer from South Korea. “It not only improved our output quality but also gave us peace of mind knowing we could rely on this machine for critical projects.” Such testimonials reflect the growing trust in the DC1090A among global buyers.

To maximize the lifespan and performance of the DC1090A, regular maintenance is essential. Here are some key tips:

The DC1090A Wheel CNC Milling Machine with BT40 spindle stands out in the competitive landscape due to its superior performance, reliability, and customer satisfaction. Whether you're involved in wheel machining, product engraving, or mold production, this machine can help you achieve better results and drive business growth.

If you're looking for a high-performance CNC solution that delivers consistent quality and efficiency, we invite you to explore the DC1090A further. Click here to learn more and request a detailed quotation today.