In today's highly competitive manufacturing landscape, the demand for high-precision equipment is more pressing than ever. Manufacturers across various industries are constantly seeking solutions that can enhance productivity, improve product quality, and reduce costs. One such solution that has emerged as a top choice for many factories is the FANUC GV2030 Heavy-Duty Machining Center.

The FANUC GV2030 is a double-column large-travel CNC milling machine that boasts several impressive technical features. Firstly, it offers an outstanding positioning accuracy of ±0.005mm. This high level of precision ensures that each part produced meets the strictest quality standards, which is crucial in industries where even the slightest deviation can lead to product failure.

Secondly, the machine has remarkable high-speed cutting capabilities. It can perform rapid machining operations, significantly reducing the production cycle time. For example, in some cases, it can cut the machining time of a complex part by up to 30% compared to traditional machines.

Another key feature is its excellent structural rigidity. The double-column design provides a stable and robust platform for machining, which helps to minimize vibrations and ensure consistent performance over long periods of operation. This rigidity also allows the machine to handle heavy cutting loads without compromising on accuracy.

In the automotive industry, the FANUC GV2030 has proven to be a game-changer. It can significantly improve the yield rate of automotive parts. For instance, a leading automotive parts manufacturer reported that after implementing the FANUC GV2030, the defect rate of their engine blocks decreased from 3% to less than 1%. This improvement not only saved costs but also enhanced the overall quality of their products.

The aerospace industry requires the machining of complex curved surfaces with extremely high precision. The FANUC GV2030 is well-suited for this task. Its advanced control system and high-precision motion control enable it to accurately machine complex aerospace components, such as turbine blades. A major aerospace company found that the FANUC GV2030 could achieve a surface finish quality that was 20% better than their previous machines, meeting the stringent requirements of the aerospace industry.

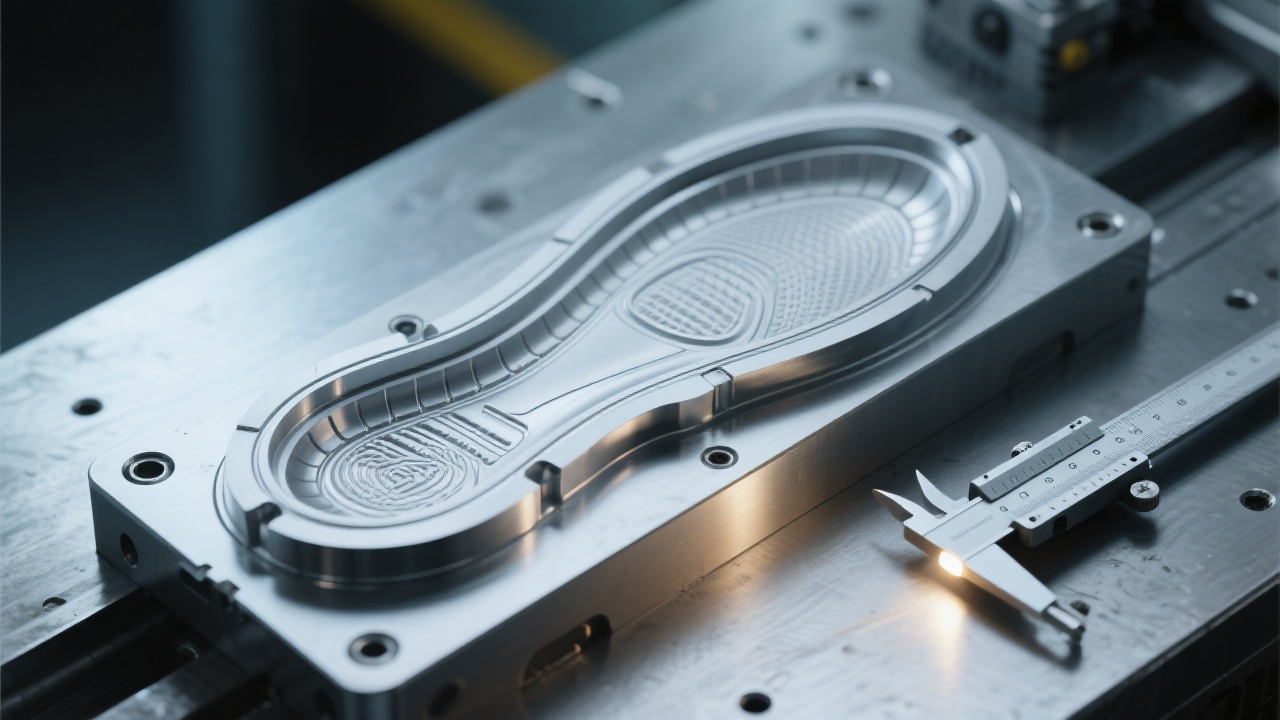

In mold manufacturing, the FANUC GV2030 can reduce the need for manual intervention. With its high-speed and high-precision machining capabilities, it can produce molds with complex geometries in a single setup. A mold-making company noted that they were able to reduce their manual polishing time by 40% after using the FANUC GV2030, resulting in significant cost savings and faster delivery times.

For engine production, consistency is key. The FANUC GV2030 ensures that each engine part is machined to the same high standard. An engine manufacturer reported that the use of the FANUC GV2030 led to a 15% improvement in the dimensional consistency of their engine components, which in turn improved the overall performance and reliability of their engines.

In the household appliance industry, where mass production is common, the FANUC GV2030 can greatly enhance production efficiency. It can quickly and accurately machine large quantities of parts, such as refrigerator compressor housings. A household appliance manufacturer found that they could increase their production output by 25% while maintaining high product quality after introducing the FANUC GV2030.

Many customers have provided positive feedback on the FANUC GV2030. One customer said, "The FANUC GV2030 has transformed our production process. It has not only improved the quality of our products but also increased our productivity. Our production cycle has been reduced by 20%, and we have seen a significant increase in customer satisfaction."

| Customer | Industry | Production Cycle Reduction | Quality Improvement |

|---|---|---|---|

| Company A | Automotive | 20% | Defect rate reduced from 3% to 1% |

| Company B | Aerospace | 30% | Surface finish quality improved by 20% |

The FANUC GV2030 is not just another machining center; it is a cornerstone for the future of production. As a 'mother machine', it can support the technological upgrade of the entire factory and the construction of a flexible manufacturing system. It allows factories to move from single-equipment operations to a more intelligent and integrated manufacturing model, enabling them to adapt quickly to changing market demands.

If you are looking to take your manufacturing business to the next level, the FANUC GV2030 is definitely worth considering. It offers a comprehensive solution that combines high precision, high efficiency, and versatility, making it an ideal choice for factories in various industries.