In today's highly competitive manufacturing landscape, the coordination and efficiency of multi - industry production have become significant bottlenecks. The large - workbench heavy - duty CNC milling machine GV2040 emerges as a game - changer in addressing these challenges. This article will delve into how this remarkable machine can revolutionize production across various industries.

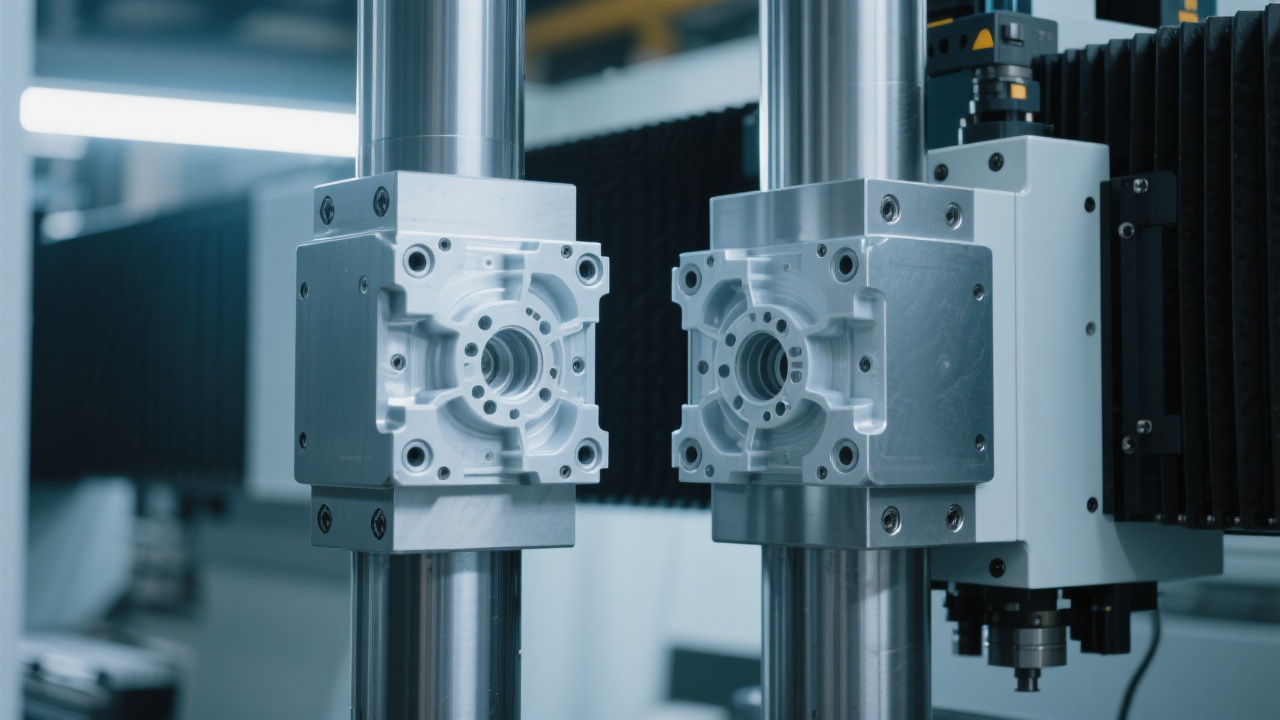

The GV2040 features a double - column and large - stroke design. The double - column structure provides excellent stability, which is crucial for high - precision machining. With a large stroke, it can handle workpieces of various sizes, catering to the diverse needs of multi - industry supporting production. For example, the stroke in the X - axis can reach up to 2000mm, and in the Y - axis, it can be 4000mm, allowing it to accommodate large - scale workpieces commonly found in industries such as aerospace and automotive manufacturing.

In the automotive parts industry, the GV2040 can achieve high - precision machining of complex parts. It can mill engine blocks, transmission housings, and other key components with an accuracy of up to ±0.01mm. This high precision ensures the smooth operation of automotive engines and transmissions, improving overall vehicle performance. According to customer feedback, using the GV2040 has increased the production efficiency of automotive parts by about 30%.

Aerospace components demand the highest level of precision and reliability. The GV2040's stability and precision make it an ideal choice for this industry. It can machine parts such as aircraft wing ribs and turbine blades. The machine's ability to maintain stable performance under long - term operation reduces the scrap rate of aerospace parts from about 5% to less than 1%, significantly saving production costs.

In mold manufacturing, the GV2040's multi - functional application is fully demonstrated. It can perform roughing, semi - finishing, and finishing operations on molds. The double - column design ensures that the machine can withstand high cutting forces during roughing, while the high - precision control system guarantees the surface finish of the mold during finishing. On average, it can reduce the mold manufacturing cycle by about 25% compared to traditional milling machines.

For engine manufacturing, the GV2040 can machine engine cylinders, pistons, and other parts with high precision. Its stable performance ensures the consistent quality of engine parts, which is essential for the power and durability of engines. Customer data shows that the use of the GV2040 has improved the qualified rate of engine parts from 90% to over 95%.

In the home appliance industry, the GV2040 can produce high - quality parts for refrigerators, washing machines, and other appliances. It can achieve fine - grained machining of small - sized parts, improving the overall appearance and performance of home appliances. With the GV2040, the production efficiency of home appliance parts has increased by about 20%.

One of our customers, a well - known automotive parts manufacturer, has been struggling with low production efficiency and high scrap rates. After introducing the GV2040, they not only increased their production efficiency by 35% but also reduced the scrap rate from 8% to 2%. Another customer in the aerospace industry reported that the GV2040 helped them win several large - scale orders due to its high - precision machining capabilities, leading to a 20% increase in annual revenue.

The large - workbench heavy - duty CNC milling machine GV2040 is a powerful tool that can solve the production challenges of multiple industries. Its stability, precision, and multi - functional application make it an indispensable equipment for modern manufacturing. If you want to learn more about how the GV2040 can transform your production process and boost your business, click here to contact us or schedule a factory visit.