In the highly competitive machining industry, the stability and precision of equipment are crucial factors that directly affect production efficiency and product quality. Many companies have faced production bottlenecks due to sub - standard equipment. For example, a medium - sized machining factory in Europe was using an old - fashioned milling machine. The machine often broke down during long - term operation, with an average of 3 breakdowns per month. Each breakdown would cause a production halt of about 8 hours, seriously affecting the delivery time of orders. Moreover, the low precision of the machine led to a product rejection rate of up to 10%, resulting in significant waste of materials and increased costs.

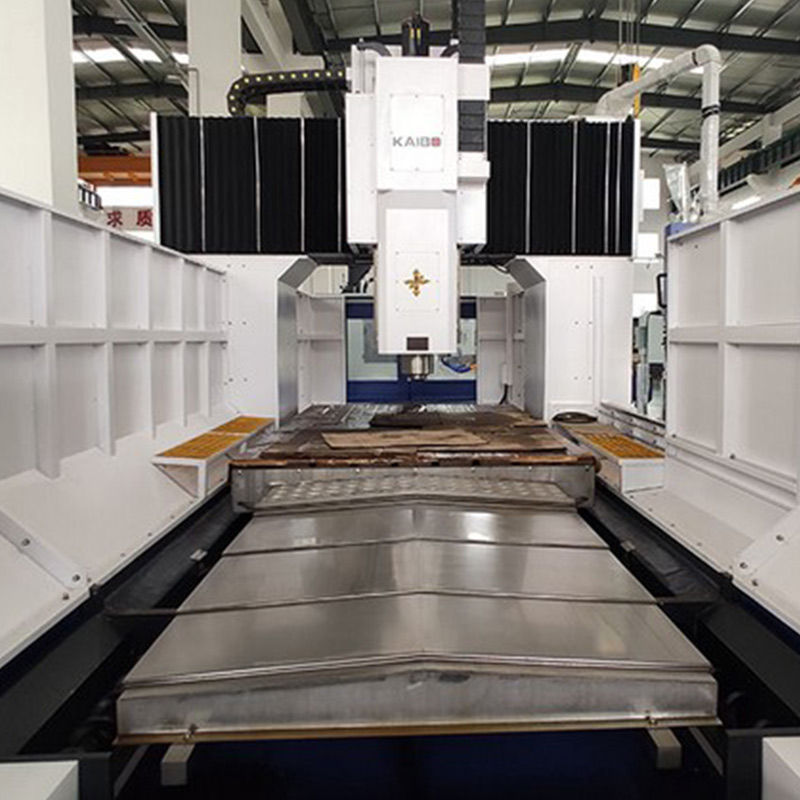

The BT40 Spindle Hub CNC Milling Machine DC1090A is renowned for its excellent stability. In practical tests, this machine can run continuously for up to 72 hours without any breakdowns. According to user feedback, after using this machine for a year, the breakdown frequency is less than once every six months. This high - level stability ensures continuous and efficient production, greatly reducing the time and cost losses caused by machine failures.

Precision is one of the core advantages of this machine. It has a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm. Such high - precision machining can significantly improve product quality. For instance, in the production of high - precision molds, the product rejection rate can be reduced from the previous 10% to less than 1%, which not only saves materials but also enhances the competitiveness of products in the market.

Compared with similar products on the market, the spindle of the BT40 Spindle Hub CNC Milling Machine DC1090A has a higher power of 15kW, which can provide stronger cutting force. Its maximum spindle speed can reach 8000r/min, enabling faster and more efficient machining. In the comparison test of machining the same workpiece, this machine can complete the task 30% faster than similar products, greatly improving production efficiency.

This machine brings remarkable improvements in machining efficiency in multiple aspects:

Let's take a look at some real - world customer cases:

| Customer Industry | Before Using the Machine | After Using the Machine |

|---|---|---|

| Automobile Parts Manufacturing | Production cycle: 15 days for a batch of 200 parts; Rejection rate: 8% | Production cycle: 10 days for a batch of 200 parts; Rejection rate: 2% |

| Aerospace Component Manufacturing | Positioning accuracy: ±0.01mm; Rejection rate: 12% | Positioning accuracy: ±0.005mm; Rejection rate: 3% |

These cases clearly demonstrate the excellent performance of the BT40 Spindle Hub CNC Milling Machine DC1090A in different industries.

Don't miss this opportunity to revolutionize your machining operations. Contact us today at [Contact Email] or visit our website [Website URL] to get more detailed information and professional consultation.