Graphite processing is a crucial industry, yet it grapples with a significant challenge: pollution from dust and metal shavings. These pollutants not only pose risks to the environment but also affect the health of workers and the precision of equipment. Enter the DC6060G, a dry vacuum graphite machining center designed to address these long - standing issues.

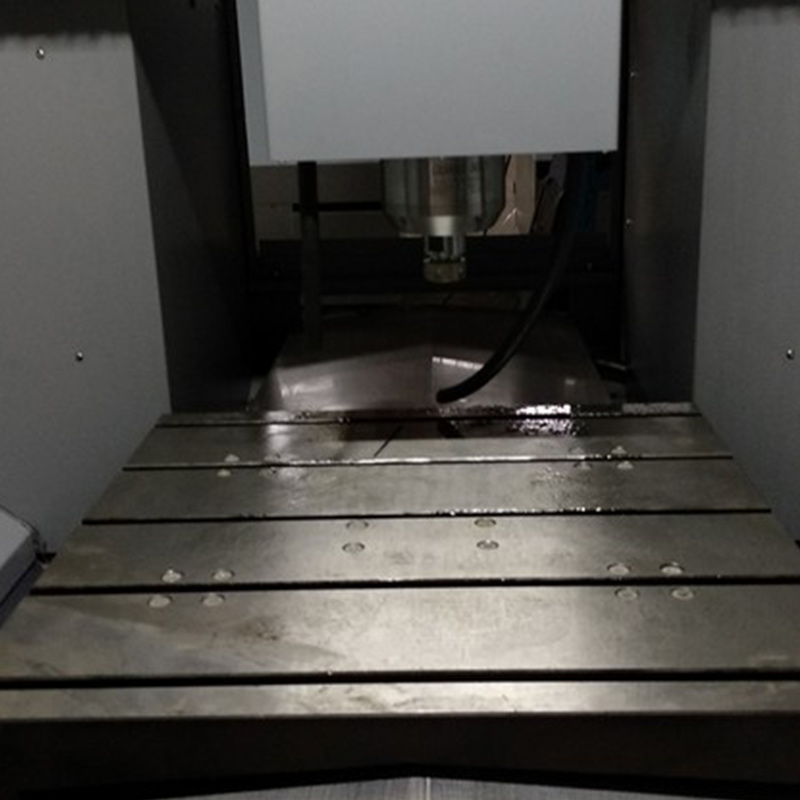

The DC6060G stands out with its fully - enclosed cover design. This design effectively prevents dust and metal shavings from escaping into the surrounding environment. In contrast, ordinary machining centers often have open or semi - open structures, allowing pollutants to spread freely. A study showed that in a standard graphite processing workshop, the DC6060G reduced the spread of dust by up to 90% compared to traditional machining centers.

Another key feature is its advanced dust collection device. With a powerful suction capacity, it can quickly capture dust and metal shavings generated during the processing. The device can handle up to 80 cubic meters of air per minute, ensuring a clean working environment inside the machining center. This is far more efficient than most common dust collection systems in the market.

Let's look at some real customer cases. A European graphite processing company was facing high costs due to frequent equipment maintenance caused by dust and metal shavings. After installing the DC6060G, they saw a remarkable reduction in maintenance costs by 60%. The air quality in their workshop improved significantly, leading to fewer sick leaves among workers and an increase in overall productivity by 30%.

In Asia, a small - scale graphite processing factory was struggling to meet environmental regulations. The DC6060G helped them achieve compliance easily. By effectively controlling pollution, they not only avoided potential fines but also enhanced their reputation in the market, attracting more high - end customers.

We encourage you to share your thoughts and experiences in graphite processing pollution control. Have you faced similar challenges? How do you think the DC6060G can fit into your production line? Leave your comments below and let's start a conversation!

If you're tired of dealing with graphite processing pollution issues, the DC6060G is your solution. It offers proven performance, cost - savings, and environmental compliance. Contact us today to learn more about how the DC6060G can transform your graphite processing operations.