In the global graphite processing industry, one of the most pressing challenges faced by manufacturers is the pollution caused by dust and metal chips. These pollutants not only pose a threat to the health of workers but also significantly affect the precision and efficiency of machining equipment. Against this backdrop, the Dry Vacuum Graphite Machining Center DC6060G emerges as a revolutionary solution, offering a brand - new experience in graphite processing from the perspective of customers.

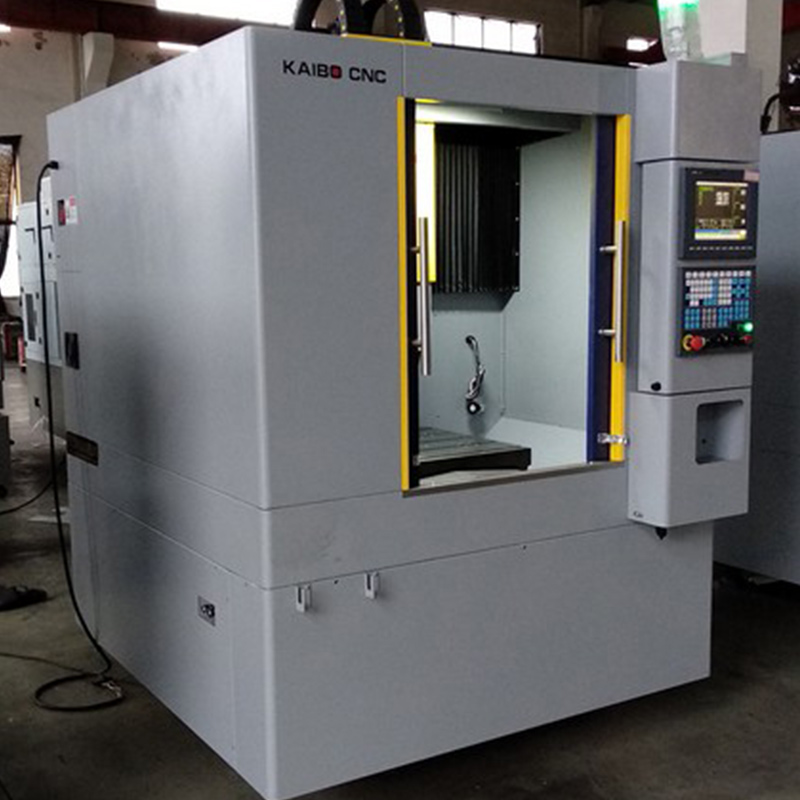

The DC6060G is equipped with a full - sealed enclosure design, which is a game - changer in the graphite processing field. This design effectively isolates the machining area from the external environment, preventing dust and metal chips from spreading. In contrast, ordinary machining centers often lack such a comprehensive sealing mechanism, resulting in a large amount of dust leakage. According to industry data, ordinary machining centers may have a dust leakage rate of up to 30%, while the DC6060G reduces this rate to less than 5%.

The dust collection system of the DC6060G is another highlight. It has a powerful suction capacity, capable of quickly and efficiently collecting dust and metal chips generated during the machining process. The system can collect up to 98% of the dust, ensuring a clean and safe working environment. The collected dust is then stored in a special container, which is convenient for centralized treatment and reduces the risk of secondary pollution.

Let's take a look at some real - world customer cases to understand the effectiveness of the DC6060G in solving pollution problems. A graphite processing company in Germany had been struggling with high dust levels in their workshop. After installing the DC6060G, they noticed a significant improvement in the air quality. The number of dust - related complaints from workers decreased by 80%, and the maintenance frequency of the machining equipment was reduced by 50% due to less dust accumulation.

Another customer, a Japanese graphite manufacturing plant, reported that the DC6060G helped them meet the strict environmental regulations in Japan. The plant's environmental compliance rate increased from 70% to 95%, which enhanced their corporate image and competitiveness in the market.

We encourage you to share your thoughts and experiences in graphite processing. Have you faced similar pollution problems? Do you think the DC6060G could be a suitable solution for your business? Leave your comments below and let's start a discussion.

The Dry Vacuum Graphite Machining Center DC6060G offers unparalleled protection and dust control capabilities. Don't miss this opportunity to improve your production environment, enhance equipment longevity, and boost your competitiveness. Contact us today to learn more about the DC6060G and take the first step towards a cleaner and more efficient graphite processing future!