In the aerospace manufacturing industry, heavy milling operations often encounter a series of challenges, including difficulty in ensuring precision, low efficiency, and complex processing techniques. These issues can significantly impede the production process and limit the quality of the final products. This article delves into a real - world case study of the GV2040 double - column large - stroke CNC milling machine, offering in - depth insights into how it helps an aerospace parts manufacturer overcome processing bottlenecks.

"Before using the GV2040, we were constantly struggling with the high - precision and high - stability requirements of heavy milling in aerospace manufacturing. The precision was hard to maintain, and the efficiency was extremely low," said a representative from the aerospace parts manufacturer.

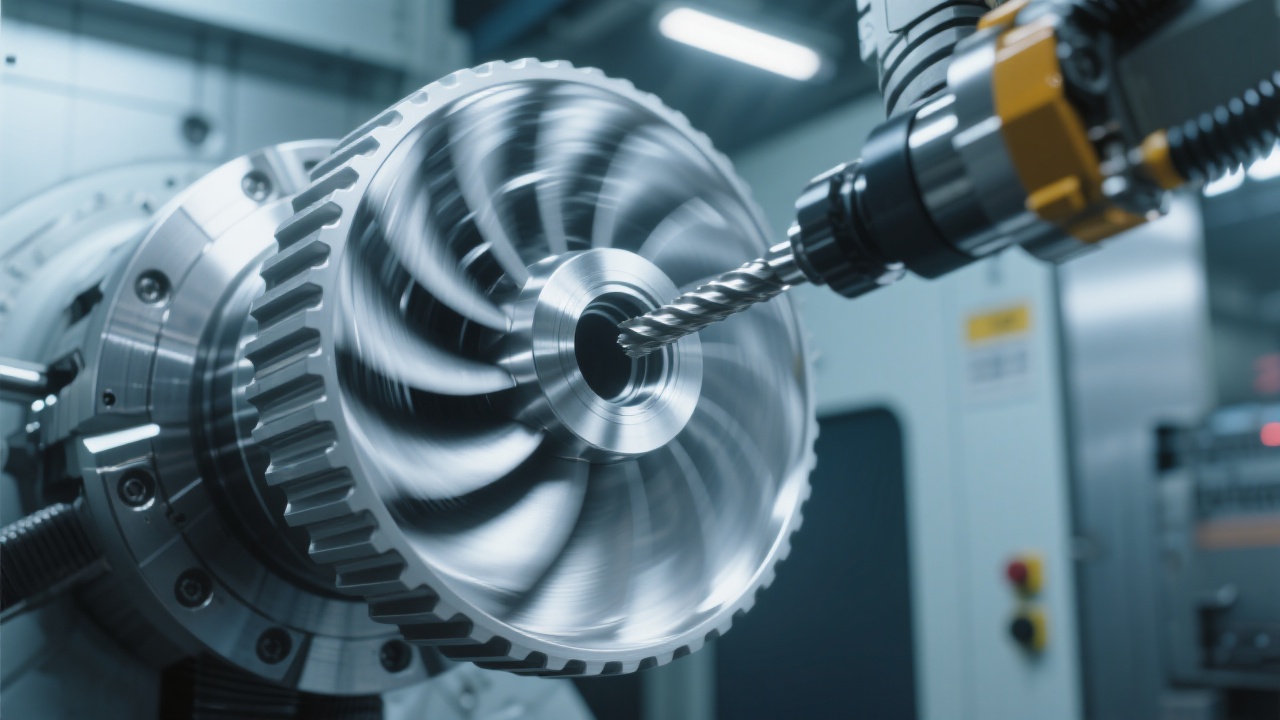

The aerospace industry has extremely high requirements for the precision and stability of heavy milling. Components such as turbine blades and engine casings demand strict tolerances and surface finishes. Traditional milling machines often struggle to meet these requirements, resulting in high rejection rates and long production cycles.

Before adopting the GV2040, the aerospace parts manufacturer faced numerous problems. The complex curved surface parts required multiple setups, which not only increased the processing time but also reduced the precision. The rejection rate was relatively high, and the overall production efficiency was low.

After implementing the GV2040, the situation changed dramatically. The high - rigidity structure design of the GV2040 allows for stable cutting performance. The complex curved surface parts can be completed in a single setup, and the yield rate has increased by more than 25%. The production cycle has also been significantly shortened, which greatly improves the overall production efficiency.

The double - column structure of the GV2040 provides excellent rigidity. This enhanced rigidity ensures stable cutting forces during heavy milling operations, reducing vibration and improving the precision of the machined parts. It can handle large - scale and heavy - duty workpieces with ease.

The large stroke of the GV2040 makes it suitable for processing complex workpieces. It can cover a larger working area, allowing for the machining of larger and more complex parts in a single operation. This feature significantly reduces the need for multiple setups and improves the overall processing efficiency.

The intelligent control system of the GV2040 plays a crucial role in improving the consistency of the machined parts. It can automatically adjust the cutting parameters according to the workpiece material and processing requirements, ensuring that each part meets the specified quality standards.

The GV2040 is not only suitable for the aerospace industry but also has wide applications in other fields such as the automotive, mold, and engine industries. In the automotive industry, it can be used for the machining of engine blocks and transmission components. In the mold industry, it can help produce high - precision molds. In the engine industry, it can process complex engine parts.

| Indicator | Before Using GV2040 | After Using GV2040 |

|---|---|---|

| Yield Rate | Less than 70% | More than 95% |

| Production Efficiency | Low | Increased by 30% |

| Failure Rate | Relatively high | Reduced by 40% |

The GV2040 serves as a "multi - scenario heavy - processing platform", which has great strategic significance and future potential. It can effectively solve the heavy - milling challenges in the aerospace industry and other related fields. Are you facing similar heavy - milling problems in your production? Let the GV2040 help you break through the processing bottlenecks. Choose GV2040, and choose reliable productivity!

We'd love to hear your thoughts on the GV2040. Do you think it can meet your production requirements? Leave your comments below!