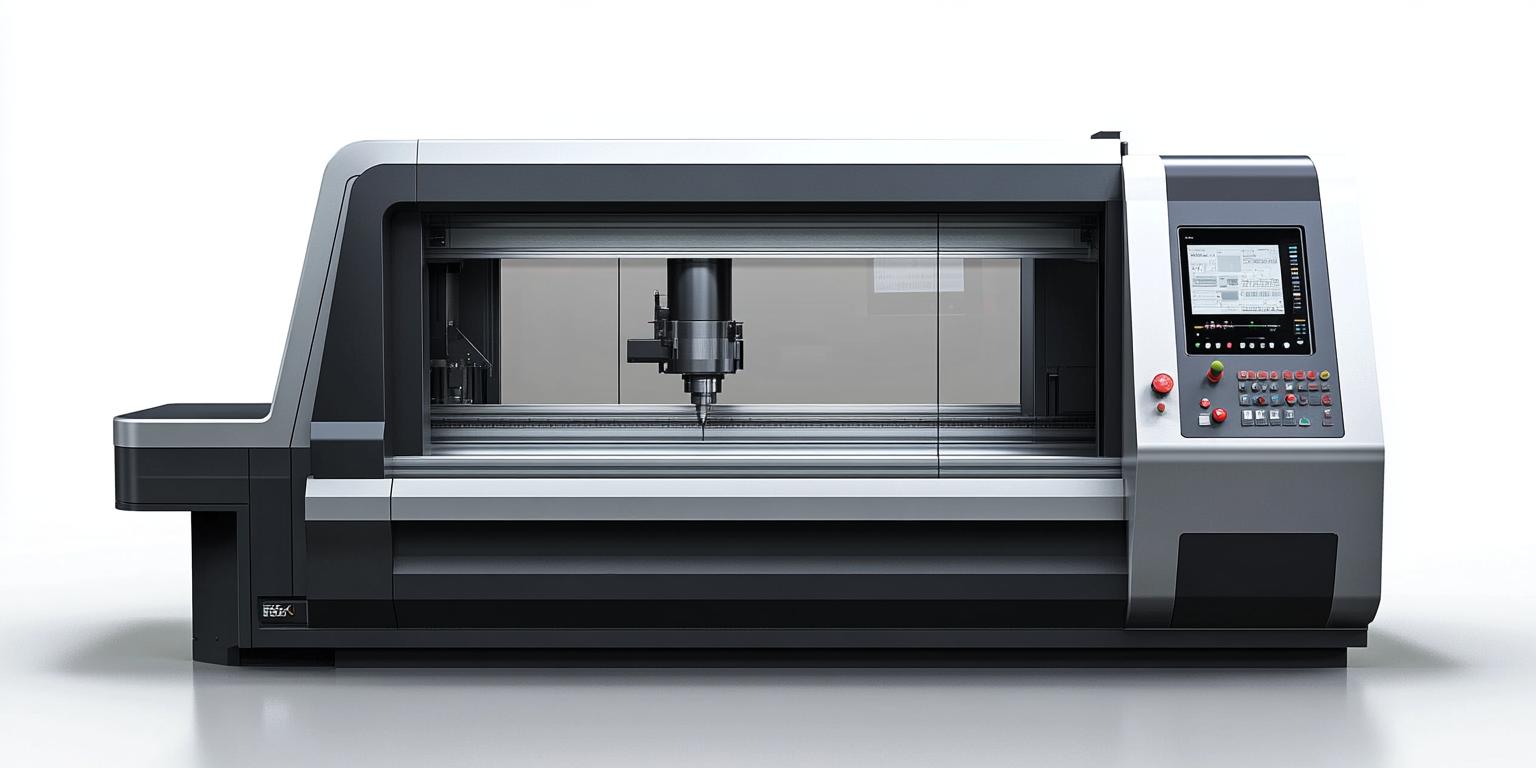

In the realm of precision manufacturing, the demand for high - quality machinery to process stainless steel workpieces is ever - increasing. The GJ1417 high - precision stainless steel CNC milling machine emerges as a game - changer, offering a comprehensive solution to the common challenges faced in stainless steel workpiece processing.

Combining in - depth technical research and market analysis, the GJ1417 showcases remarkable core technologies and performance benefits. At its heart lies the use of high - quality stainless steel material. This material offers excellent durability and corrosion resistance. In fact, tests have shown that it can withstand up to 10 years of continuous use in normal industrial environments without significant signs of corrosion, far outperforming many of its competitors in the market.

The intelligence of the CNC system in the GJ1417 is one of its standout features. With advanced automation programming capabilities, operators can significantly reduce programming time. For example, a complex programming task that would typically take 8 hours on a traditional milling machine can be completed in just 2 hours on the GJ1417. Additionally, the real - time monitoring function allows operators to keep a close eye on the machining process, detecting and correcting any potential issues immediately, which helps improve the overall quality of the finished products.

The GJ1417 is highly adaptable when it comes to processing different types of workpieces. It can handle workpieces with a wide range of sizes, from small components with a diameter of 50mm to large - scale parts up to 2000mm in length. Moreover, it can process complex shapes with high precision, such as intricate curves and irregular geometries, making it suitable for a variety of industries, including aerospace, automotive, and medical device manufacturing.

Let's take a look at some real - world examples of how the GJ1417 has made a difference. A leading aerospace company was struggling with the high cost and low efficiency of processing stainless steel turbine blades. After implementing the GJ1417, they were able to reduce production time by 30% and improve the precision of the blades, leading to a significant increase in product quality and a reduction in waste.

Another case is a medical device manufacturer. They needed to produce high - precision stainless steel surgical instruments. The GJ1417's ability to handle complex shapes and maintain high precision allowed them to meet the strict quality standards of the medical industry, resulting in an expansion of their market share.

The GJ1417's main competitive advantages lie in its ability to meet the high - precision processing requirements of various industries. Its long - lasting durability and intelligent system not only improve production efficiency but also reduce long - term operating costs. For businesses looking to invest in a reliable and high - performance milling machine, the GJ1417 offers excellent value for money.

If you're in the market for a high - precision stainless steel CNC milling machine that can boost your productivity and product quality, look no further than the GJ1417. Click here to learn more about how the GJ1417 can transform your manufacturing operations.

We'd also love to hear from you. Do you have any specific questions about the GJ1417 or your stainless steel processing needs? Leave a comment below, and our experts will get back to you as soon as possible.