Are you a factory manager or procurement decision-maker facing the challenges of factory upgrade and transformation? In this article, we'll explore how the FANUC GV2030 Heavy-duty Machining Center can be your secret weapon to boost production efficiency and achieve a successful upgrade.

During the factory upgrade process, you're likely grappling with several issues. High production costs, low efficiency, and the inability to meet diverse market demands are some of the common pain points. You need a solution that can not only improve productivity but also enhance product quality while reducing costs.

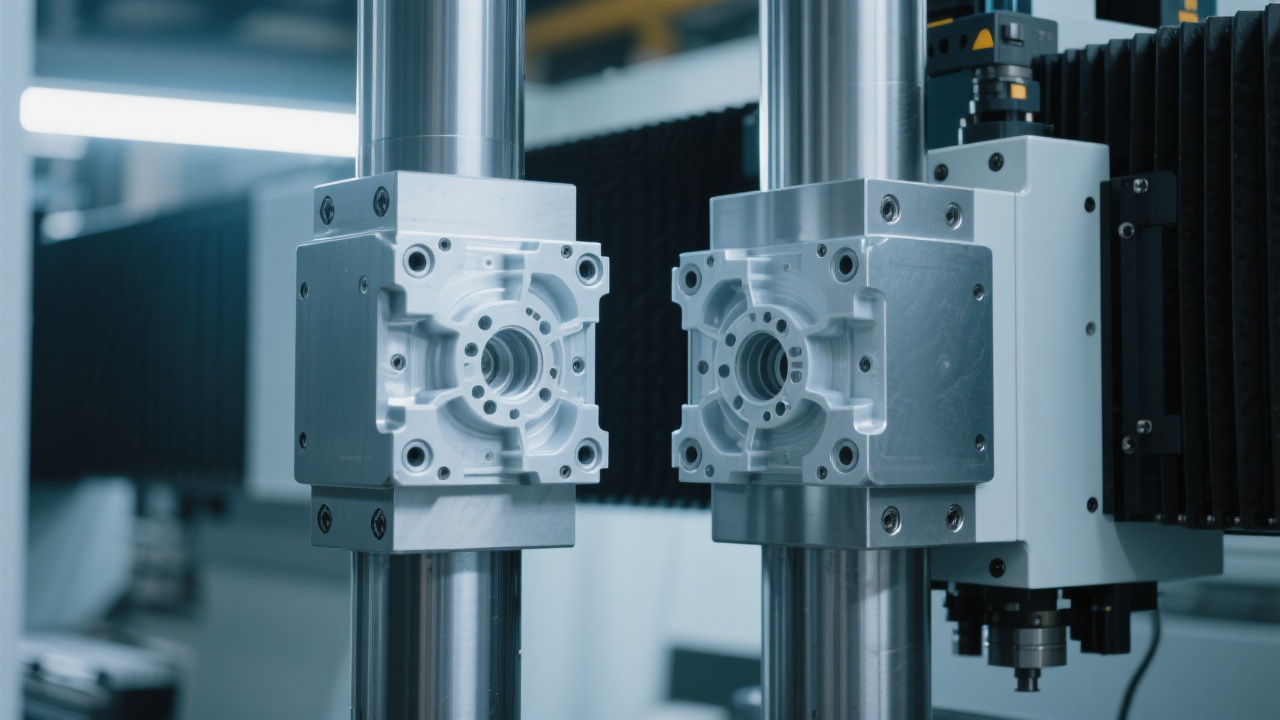

The FANUC GV2030 features a large stroke, which allows it to handle a wide range of workpiece sizes. With a larger working area, you can process more complex and larger parts in a single setup. This reduces the need for multiple setups and repositioning, saving valuable time and increasing overall efficiency. For example, in a typical metalworking factory, the large stroke of the GV2030 enables it to machine components that are up to 2000mm in length and 3000mm in width, which is 30% larger than some traditional machining centers.

Precision is crucial in modern manufacturing. The FANUC GV2030 is equipped with advanced control systems and high-quality components, ensuring extremely high precision in machining. It can achieve a positioning accuracy of ±0.005mm and a repeatability of ±0.003mm. This high precision results in better product quality, fewer rejects, and less rework. In industries such as aerospace and automotive, where precision is of utmost importance, the GV2030 can meet the strictest quality requirements.

The FANUC GV2030 is not limited to a single industry or type of processing. It can be used in various fields, including mold making, machinery manufacturing, and automotive parts production. Whether you need to perform milling, drilling, boring, or tapping operations, the GV2030 can handle them all with ease. Its versatility makes it a valuable asset for factories that need to adapt to changing market demands.

Let's take a look at some real examples of how the FANUC GV2030 has helped factories improve their production efficiency and reduce costs. A machinery manufacturing factory was facing challenges in meeting the increasing demand for large and complex parts. After installing the GV2030, they were able to reduce the production time for a particular component by 40%. This not only increased their output but also reduced the labor cost associated with the production process. Another factory in the automotive industry was struggling with high reject rates due to poor precision. The GV2030's high precision capabilities helped them reduce the reject rate from 8% to less than 2%, resulting in significant cost savings.

| Benefit | Average Improvement |

|---|---|

| Production Efficiency | 30% - 50% |

| Cost Reduction | 20% - 35% |

| Reject Rate | Reduced by 60% - 80% |

We encourage you to share your thoughts and questions about the FANUC GV2030. Do you have any concerns about its compatibility with your existing production line? Or are you curious about how it can specifically benefit your factory? Leave your comments below, and our experts will be happy to answer them.

Don't miss out on the opportunity to transform your factory and stay ahead of the competition. The FANUC GV2030 is the key to achieving intelligent and efficient production. Click here to learn more and start your production upgrade today!