The large mold processing industry has been undergoing significant transformations in recent years. With the rapid advancement of technology, manufacturers are increasingly focusing on innovation to improve efficiency and meet the growing demands of various sectors. This article will explore the current trends and technological innovations shaping the industry, highlighting the DC2025 gantry CNC milling machine's advantages.

One of the most prominent trends in the large mold processing industry is the shift towards automation. Organizations are adopting automated systems to enhance production efficiency and reduce human error. The integration of AI and machine learning technologies is also being utilized to improve process accuracy and predictive maintenance, minimizing downtime.

Another vital trend is the emphasis on sustainability. Manufacturers are increasingly prioritizing eco-friendly materials and processes, contributing to reduced carbon footprints and waste. Utilizing recyclable materials in large mold production not only enhances the environmental credibility of companies but also aligns with global sustainability goals.

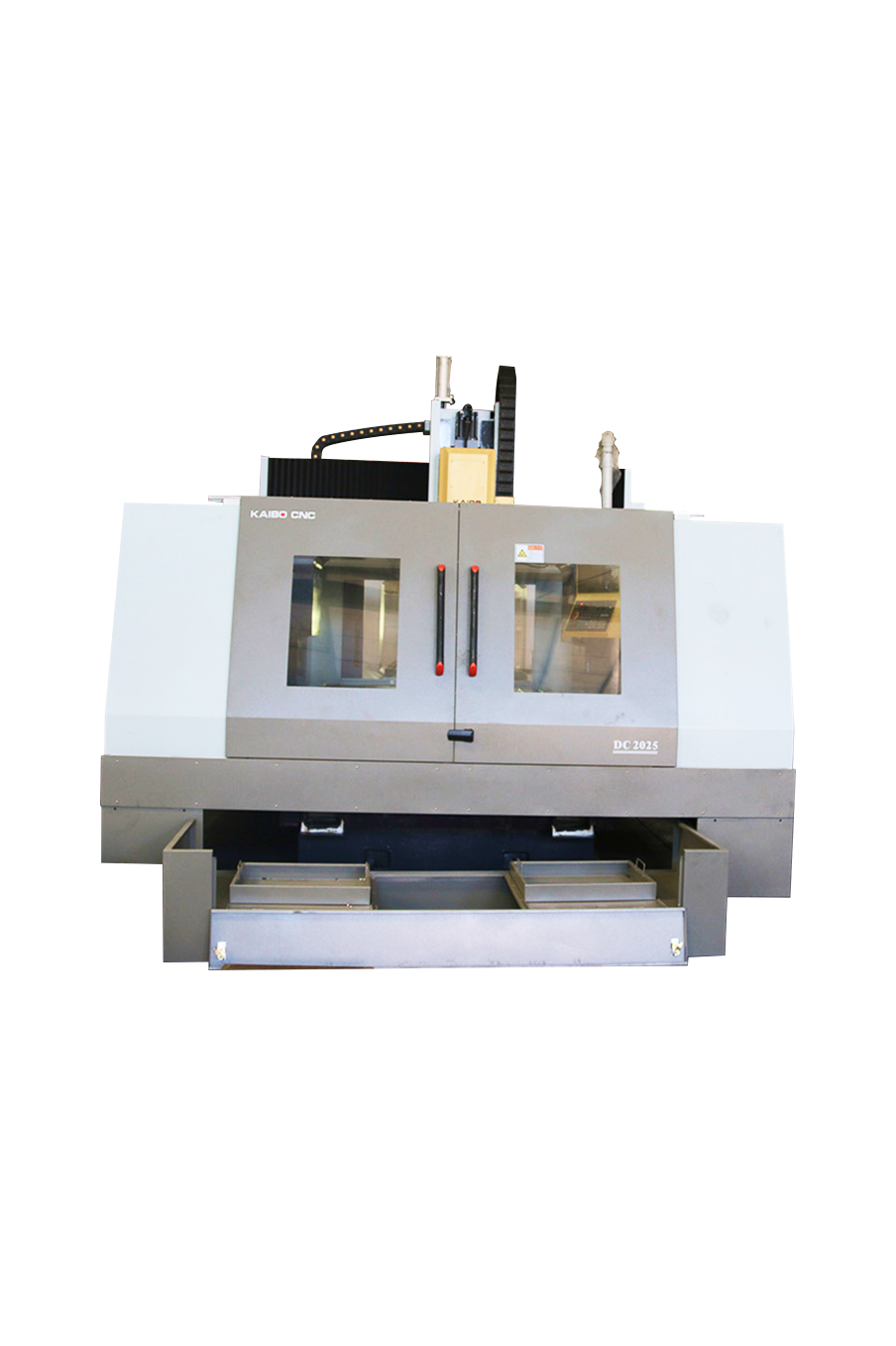

Technological innovation is at the forefront of the large mold processing industry. The introduction of advanced machining tools, such as the DC2025 gantry CNC milling machine, plays a pivotal role in revolutionizing manufacturing processes.

The DC2025 offers numerous advantages, including high precision and versatility, making it ideal for complex mold designs. Its robust construction ensures stability during high-speed machining, ultimately leading to a reduction in production time and improved output quality.

Moreover, the machine's advanced software integration provides users with real-time data analytics, facilitating better decision-making and process optimization. The ability to handle larger workpieces further positions the DC2025 as a leader in responding to market demands.

As the large mold processing industry continues to evolve, embracing technological innovations and adapting to new trends will be crucial for manufacturers. The DC2025 gantry CNC milling machine stands out as a significant advancement, empowering companies to meet emerging market needs efficiently. By focusing on automation and sustainability, the industry can pave the way for a more productive and eco-friendly future.