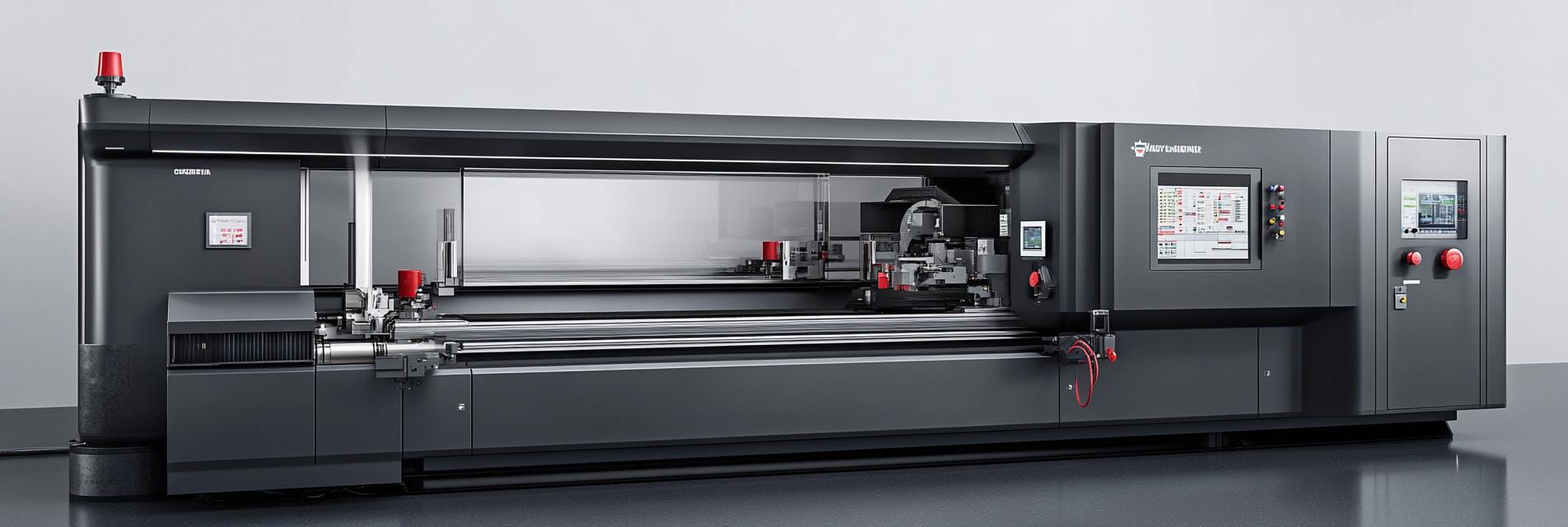

As a passionate advocate for efficient industrial processes, I've found that the circulation filtration system in wET Graphite machining centers plays a vital role in optimizing performance. In this article, I will delve into its essential components and the multitude of benefits it offers.

The filtration system primarily consists of three key components: the filter, the pump, and the reservoir. These elements work together to ensure that cutting fluids remain clean and effective during various machining operations. By filtering out contaminants and circulating clean coolant, we can significantly extend the lifespan of both the tooling and the equipment.

One of the most compelling reasons to implement a circulation filtration system is its impact on operational efficiency. With better control of the machining conditions, companies can experience reduced downtime and lower operational costs. Furthermore, maintaining clean cutting fluids leads to improved surface finishes and dimensional accuracy in graphite processing.

I was once involved in a project where we transitioned to using a circulation filtration system. The results were remarkable; the machining center's throughput increased by 30%, and machining costs dropped significantly due to fewer tool changes and enhanced reliability.

In conclusion, investing in a reliable circulation filtration system for wet graphite machining centers not only enhances efficiency but also guarantees optimal performance. It is a critical step toward adopting a more sustainable manufacturing approach.