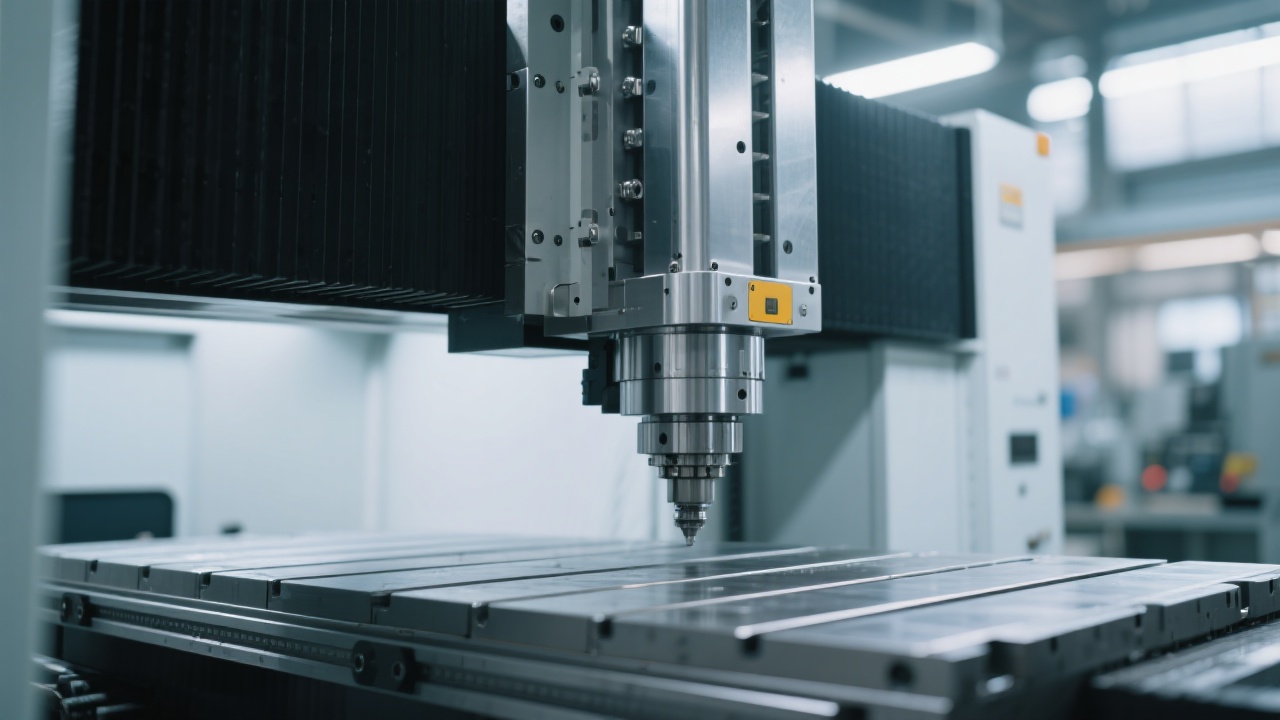

The DC1090A medium-sized double-column CNC milling machine is a remarkable piece of equipment designed for the demanding needs of the engraving and mold processing industries. At its core, the BT40 spindle serves as the heart of this machine, bringing a host of advantages.

The BT40 spindle is known for its high power and speed. It can reach a maximum speed of 8000 RPM, which enables it to handle a wide range of materials with ease, including wood, plastic, and various metals. This high-speed operation significantly reduces the processing time for each workpiece. For example, in a typical engraving task on a metal plate, the DC1090A with the BT40 spindle can complete the job 30% faster compared to some other machines in the same class.

In terms of precision, the DC1090A boasts a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm. These high-precision parameters ensure that the machine can produce intricate and detailed engravings and molds. Whether it's a fine pattern on a jewelry mold or a complex contour on an automotive part, the DC1090A can reproduce the design with high fidelity.

In the engraving and mold processing industries, there are several common pain points that users often face. One of the main issues is the low efficiency caused by slow processing speeds and frequent tool changes. The DC1090A's BT40 spindle, with its high-speed operation and efficient tool-changing system, can effectively solve this problem. The tool-changing time is reduced to within 3 seconds, which means less downtime and more continuous production.

Another pain point is the poor surface finish of the processed workpieces. Low-quality surface finishes can lead to additional post-processing steps, increasing the overall production cost. The high precision and stability of the DC1090A ensure a smooth surface finish. In a case study of a mold processing factory, after switching to the DC1090A, the percentage of workpieces requiring additional surface finishing was reduced from 20% to less than 5%.

Let's take a look at some data to further illustrate the performance of the DC1090A. In a production line comparison test, the DC1090A was able to produce 150 pieces of engraved parts per day, while a competing machine could only produce 100 pieces under the same working conditions. This represents a 50% increase in production capacity.

There is also a real - world case from a well - known jewelry engraving company. They were struggling with low - quality engravings and long production cycles. After installing the DC1090A, they saw a significant improvement. The defect rate of their engraved products dropped from 10% to 2%, and the production cycle was shortened by 40%. This not only improved their product quality but also increased their market competitiveness.

In the highly competitive market of CNC milling machines, the DC1090A stands out with its excellent performance and cost - effectiveness. Its combination of high - speed processing, high precision, and stability gives it an edge over many competitors. For users, this means higher production efficiency, better product quality, and ultimately, more profit.

The DC1090A also offers a user - friendly interface and easy - to - operate control system. Even for operators with limited experience, they can quickly get familiar with the machine and start production. This reduces the training time and cost for the users.

The DC1090A medium - sized double - column CNC milling machine, with its powerful BT40 spindle, high precision, and ability to address industry pain points, is an ideal choice for the engraving and mold processing industries. It can help users improve production efficiency, enhance product quality, and gain a competitive advantage in the market.

If you are looking for a reliable and high - performance CNC milling machine for your engraving or mold processing business, don't miss the DC1090A. Click here to learn more about the DC1090A and how it can transform your production process!