In the field of graphite processing, dust corrosion has long been a major headache for manufacturers. Graphite dust and metal chips can easily corrode and contaminate machine tools, leading to reduced machine life, increased maintenance costs, and decreased processing efficiency. These issues not only affect the normal operation of enterprises but also pose challenges to the quality and stability of products. However, the wet - flush graphite machining center DC6060G offers a revolutionary solution.

The DC6060G is an upgraded version based on the CNC milling machine DC6060A. Through in - depth research and development, engineers have made a series of technical improvements. Compared with traditional models, the DC6060G has a 20% improvement in overall structural stability, which provides a solid foundation for high - precision machining.

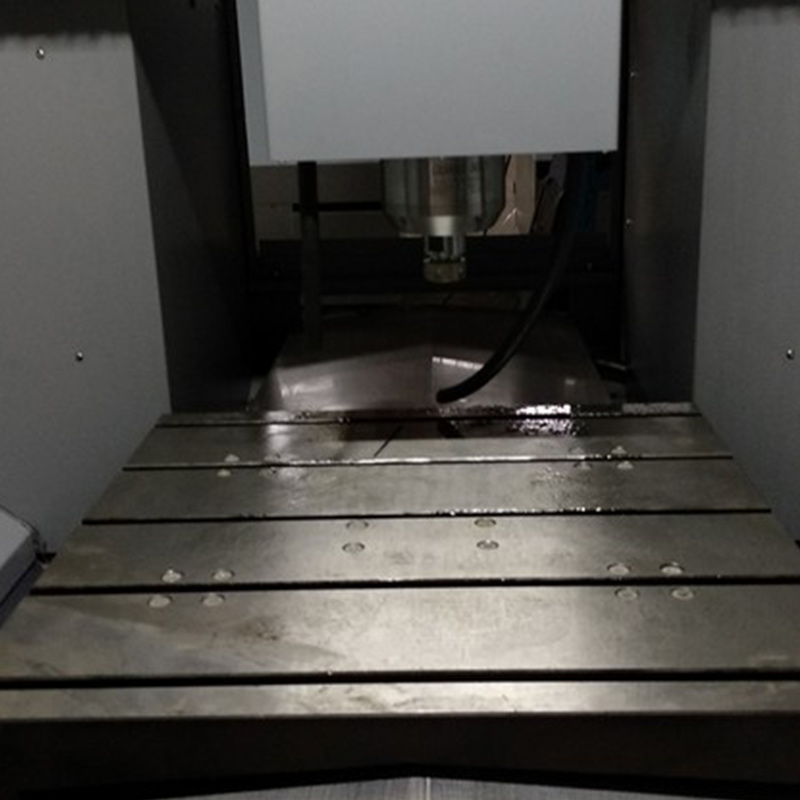

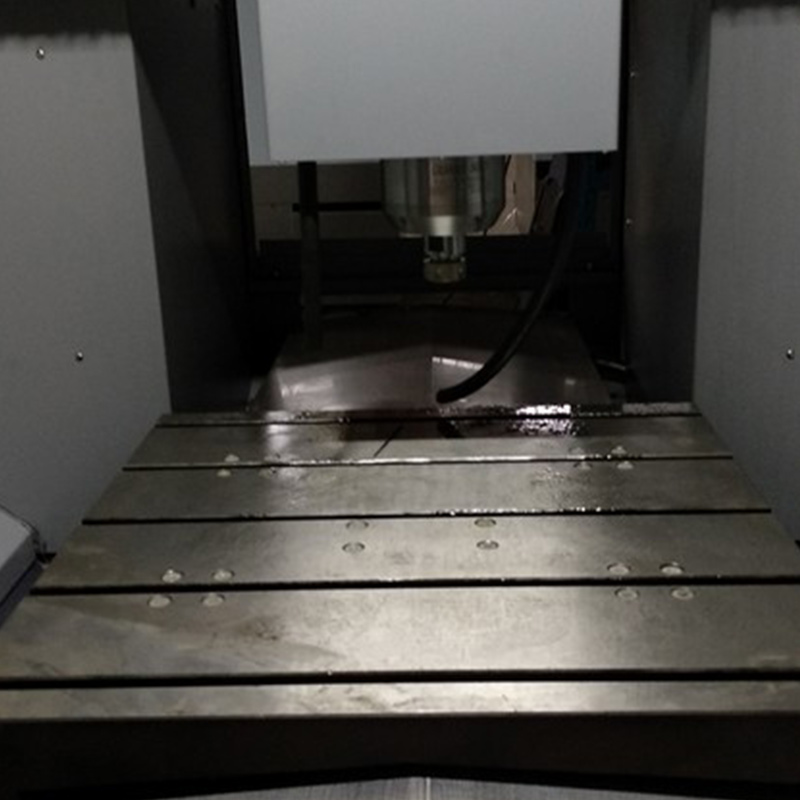

One of the key features of the DC6060G is its fully sealed enclosure design. This design acts as a reliable shield for the internal components of the machine tool. The fully sealed enclosure effectively prevents graphite dust and metal chips from entering the machine, reducing the risk of corrosion and damage to internal parts. According to our tests, this fully sealed design can block more than 98% of dust and debris, greatly extending the service life of the machine tool.

The wet - flush system of the DC6060G is another core innovation. This system uses high - pressure water to flush the machining area, quickly removing graphite dust and metal chips. The working principle is simple yet effective. The high - pressure water not only cleans the machining area but also cools the cutting tool, improving cutting efficiency and tool life. In actual production, the wet - flush system can increase the cutting speed by 15% and reduce tool wear by 25%.

A graphite product manufacturer in Germany had been suffering from low machining efficiency and high machine maintenance costs due to dust corrosion. After purchasing the DC6060G, the situation improved significantly. In the first three months of use, the machine's downtime for maintenance was reduced by 40%, and the product qualification rate increased from 85% to 95%. The manufacturer also reported a 30% increase in overall production efficiency, which directly translated into increased profits.

In addition, a Chinese graphite processing enterprise also experienced similar benefits. By using the DC6060G, they were able to take on more high - end orders, expanding their market share in the global graphite processing industry.

If you are also troubled by dust corrosion in graphite processing and want to improve machining efficiency and product quality, the wet - flush graphite machining center DC6060G is your ideal choice. Click here to learn more about the DC6060G or contact our online customer service or call our consulting hotline for detailed information.